MFD

MUGEN COATING Flat Drill

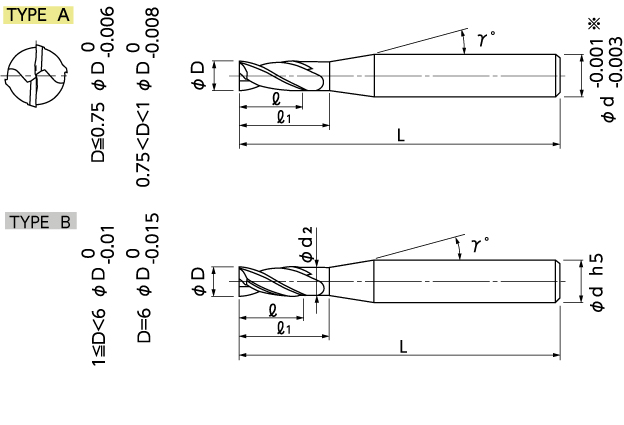

●Small diameter drill with flat end profile, tool design developed and optimized for different sizes.

●Developed for the precise drilling field. Standardized every 0.05 sizes from Φ0.1~Φ0.95, and every 0.1 for over Φ1.

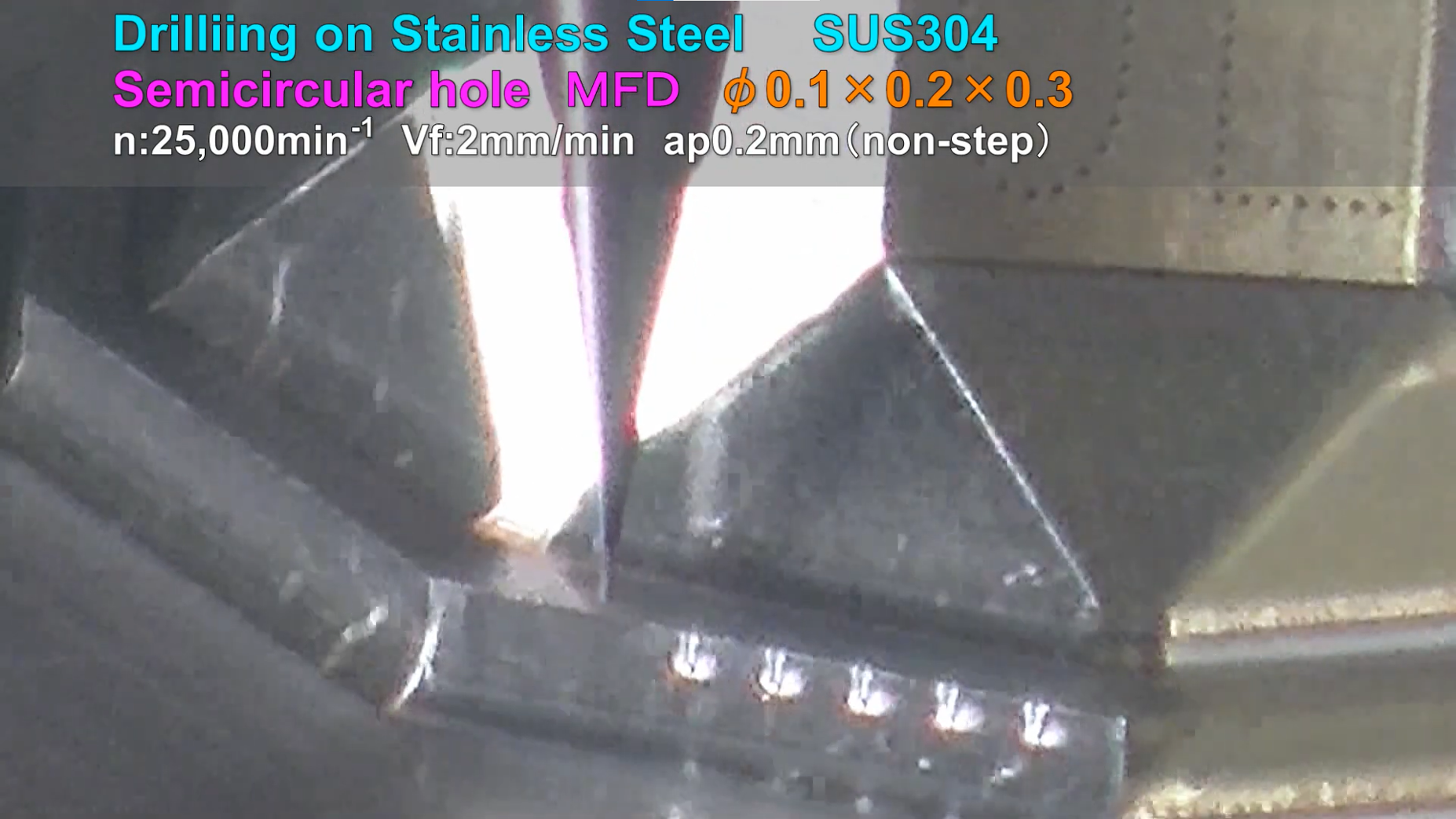

●Stable drilling is realized in various scenes such as inclined surface and curved surface!

●High efficient counter boring is available, also possible to reduce the back burr.

Coating

MUGEN COATING

Material

Micro Grain Carbide

Number of Flutes

2 Flutes

Helix Angle

20°/30°

φd-0.001/-0.003(D<1) &

h5(D≧1)

Applications

Flat Drilling

Work Materials

Machinable indication by  ,

,

| Carbon Steel | Alloy Steel | Prehardened Steel | Hardened Steel | Stainless Steel | Heat Resistant Alloy | Aluminum Alloy | Copper | Resin | Graphite | Hard Brittle Material | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ~ 52HRC |

~ 60HRC |

~ 65HRC |

~ 70HRC |

||||||||||

| Carbon Steel | Heat Resistant Alloy |

|||

|---|---|---|---|---|

| Alloy Steel | Aluminum Alloy | |||

| Prehardened Steel |

Copper | |||

| Hardened Steel |

~ 52HRC |

Resin | ||

| ~ 60HRC |

Graphite | |||

| ~ 65HRC |

Hard Brittle Material |

|||

| ~ 70HRC |

Hard Brittle Material |

|||

| Stainless Steel | ||||

Machining Video