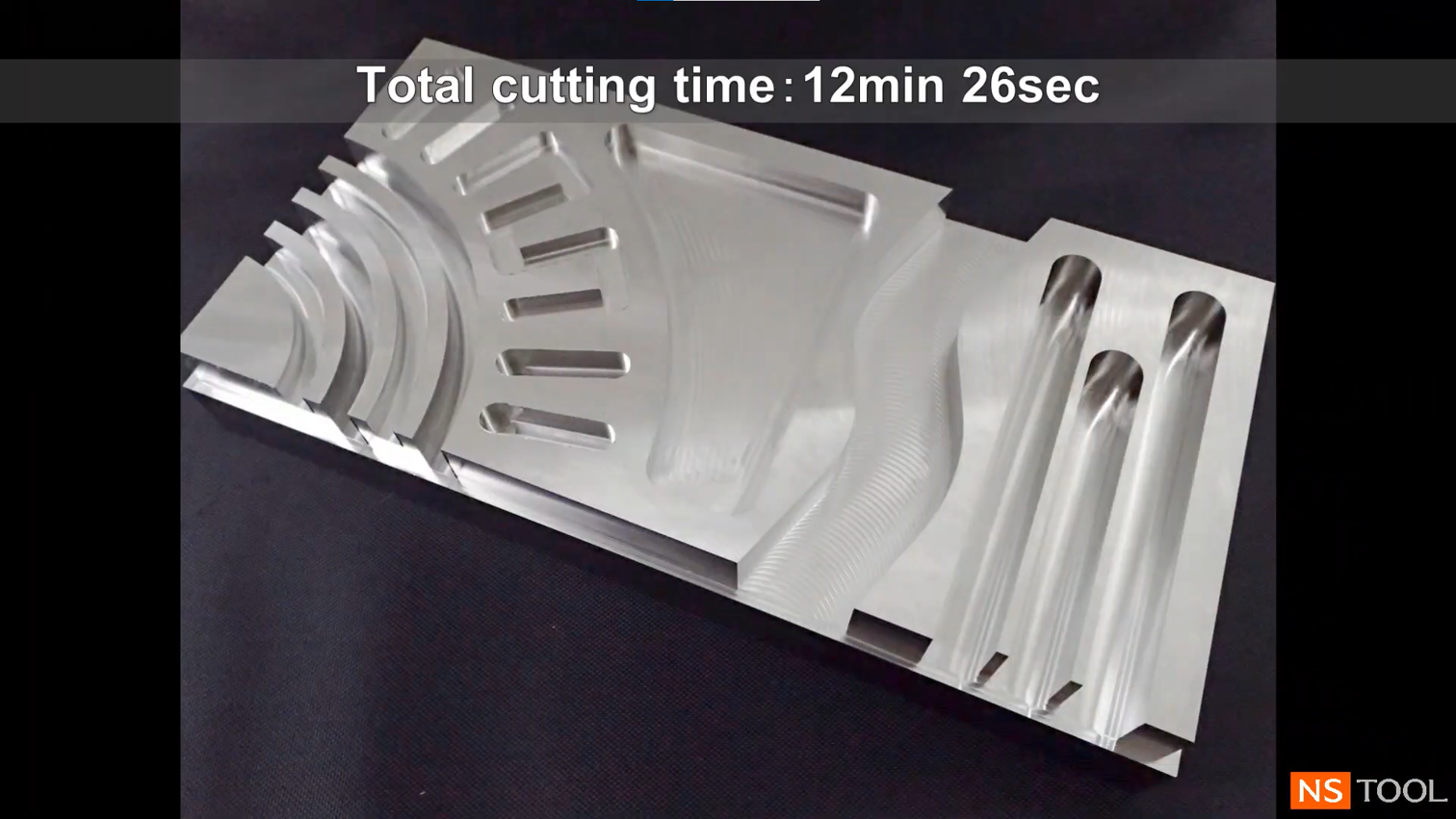

MSUSZ440

MUGEN COATING PREMIUM 4-Flute High Efficient ”Z” End Mill for Stainless Steels

●Unequal flute spacing,unequal helix angle and high rigid end profile design to minimize chatter realize high efficient machining.

●New developed special edge profile realized multi-functional performance of side milling,slot milling and plunging approaches on stainless steel.

●Optimized high heat-resistance MUGEN COATING PREMIUM to realize stable long time machining.

●Total 62 sizes,some sizes line up with L/D=2 or 3.

Coating

MUGEN COATING PREMIUM

Material

Micro Grain Carbide

Cutting Possibility of Work Material Hardness

Up to 40HRC

Number of Flutes

4 Flutes

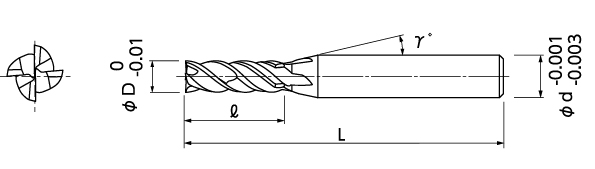

Helix Angle

40°/42°

φd-0.001/-0.003

Applications

Side Milling

Applications

Slot Milling

Applications

Face Milling

Applications

Pulunging Milling

Work Materials

Machinable indication by  ,

,

| Carbon Steel | Alloy Steel | Prehardened Steel | Hardened Steel | Stainless Steel | Heat Resistant Alloy | Aluminum Alloy | Copper | Resin | Graphite | Hard Brittle Material | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ~ 52HRC |

~ 60HRC |

~ 65HRC |

~ 70HRC |

||||||||||

| Carbon Steel | Heat Resistant Alloy |

|||

|---|---|---|---|---|

| Alloy Steel | Aluminum Alloy | |||

| Prehardened Steel |

Copper | |||

| Hardened Steel |

~ 52HRC |

Resin | ||

| ~ 60HRC |

Graphite | |||

| ~ 65HRC |

Hard Brittle Material |

|||

| ~ 70HRC |

Hard Brittle Material |

|||

| Stainless Steel | ||||

Machining Video