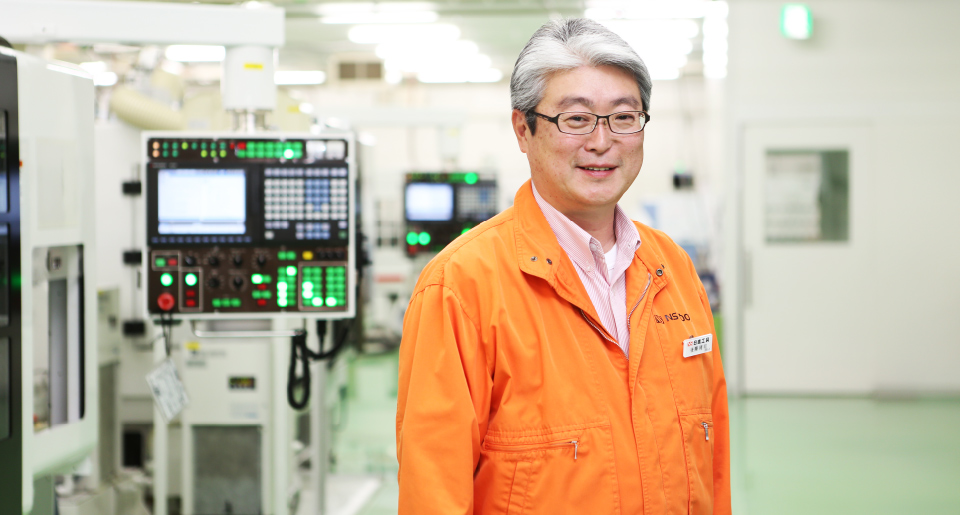

Vice President & Representative Director at NS TOOL Co., Ltd.Interview with Takashi Goto

July 20, 2017

What sort of ‘monozukuri’ does the Sendai Factory aim for?

When it comes to ‘monozukuri’, it’s not just the level of quality that we care about. We also care about the “absolute quality” achieved through our ongoing work to protect that high quality while delivering the same high-precision products.

In recent decades we have been steadily developing technologies in the field of cemented carbide small-diameter end mills. Some of the products our customers create are tiny components invisible to the naked eye. It’s our job to create reliable functionality for objects whose existence can’t even be confirmed, to create things that can’t be seen. Reliably delivering high-precision products that exceed the tolerances specified in the production diagrams is our pride as a tool manufacturer.

Production/development sites created by human hands.

We believe that it is people who support our ‘monozukuri’. At the same time, we have been vigorously introducing the latest production and inspection machinery since our company’s founding. By doing so, we have managed to automate almost all of our processes as of this writing. We have pursued automation in an effort to completely eliminate human error.

Then, someone may ask, are people supporting? People create the methods, ideas, and ingenuity necessary for production. Whether it’s thinking about the production line or building the production machines, we could say that most of the factory was made by our hands.

The “TGM” that operates as our primary small-diameter end mill production machine was developed in-house by NS TOOL. We make adjustments to most of the machines we order from manufacturers, insofar as we can. Our Sendai Factory also makes frequent changes to factory layout, but we move machines with our hands when necessary. We are flexibly pursuing optimization in all of our processes. Some problems can be solved with small alterations. However, we enact solutions at any cost, even if they require complete machine shutdowns for days. NS TOOL’s Sendai Factory is a living factory.

Becoming a factory that will move our customers.

This sort of flexible response capability is one of our company’s strengths, one that we are certain can only be created with people’s hands. It’s not just initiatives towards maintaining and improving productivity and product quality; it’s not allowing production to stop during times of disaster and such. It’s ingenuity enabling quick recovery even when something stops; it’s securing inventory quantity to promise that issues will never arise for the customer. We’ve actively moved forward with risk strategies such as these since our founding. Today, having experienced the Great East Japan Earthquake, we’ve gained a sobering new recognition of their importance. We believe that the power to respond to customer requests is created by human enthusiasm—how deeply people can think.

In some instances our R&D Center gathers machine tools of the same models our customers use in order to run tests in the same environments. We do this in the belief that we must share the customer’s experience in exacting detail that we will never succeed in increasing machining precision if we don’t. Sometimes we use our experience to support customers who are dealing with new kinds of machining. There’s no substitute for relationships of trust built this way.

I regard the Sendai Factory as a key sales tool for NS TOOL. Of course we want customers to like our products, but we also want them to visit our factory and our initiatives, and to empathize and be moved by them. Our customers are the professionals of ‘monozukuri’. Our goal is to receive recognition from people like them.