Product

MUGEN COATING

High Efficient ”Z” End Mill for Carbon Steels

MSCZ440・MSCZ440-LN

Product

MUGEN COATING

High Efficient ”Z” End Mill for Carbon Steels

MSCZ440・MSCZ440-LN

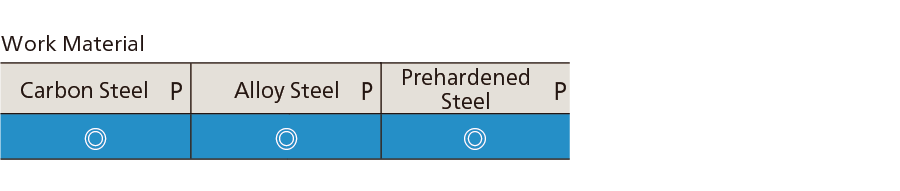

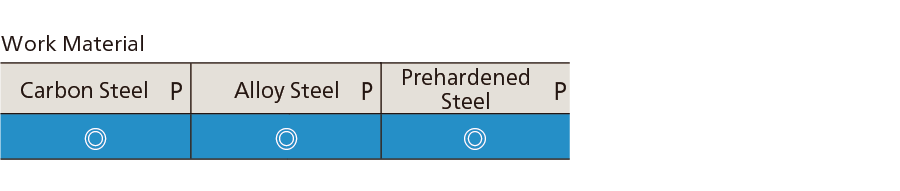

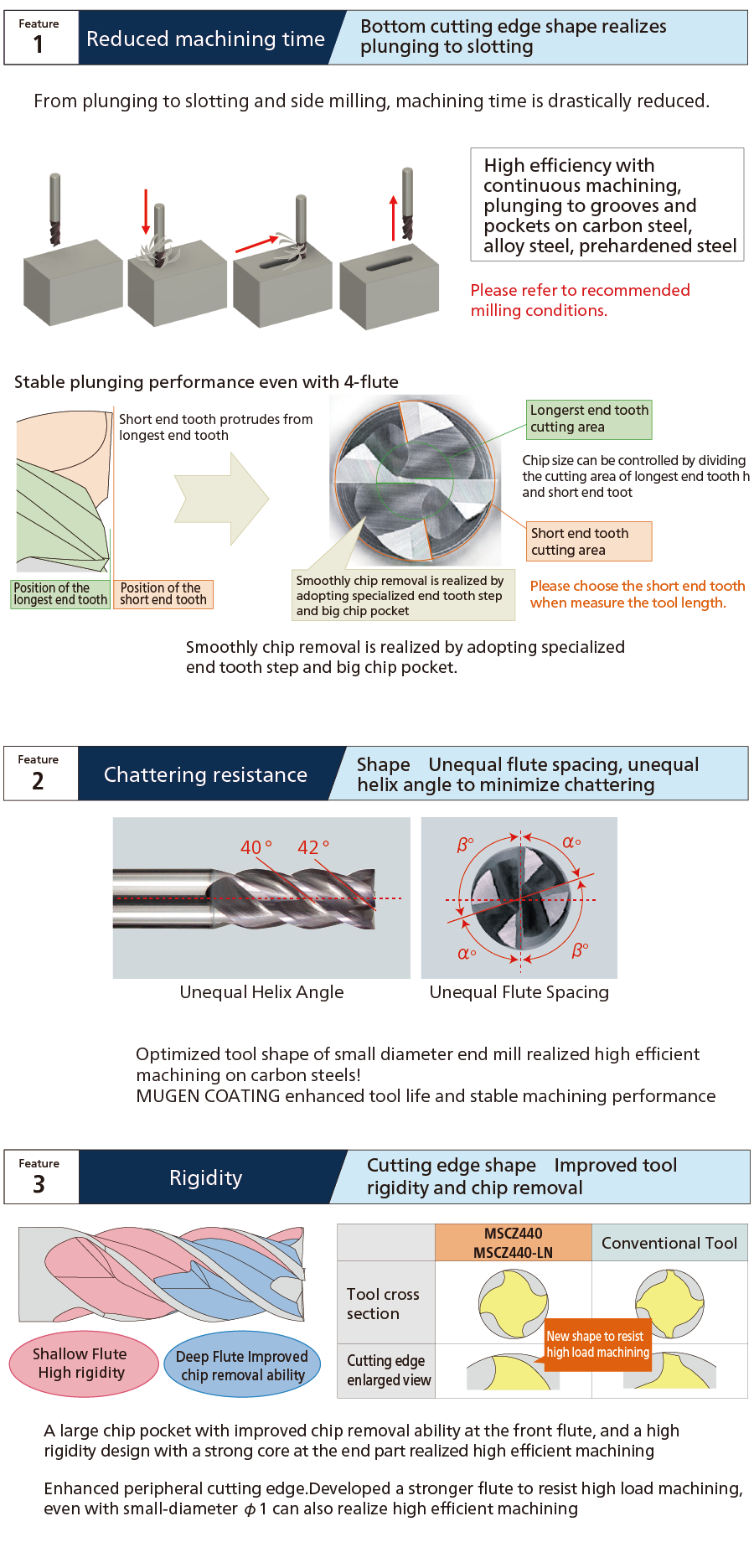

● Unequal flute spacing, unequal helix angle and high rigid end profile design to minimize chatter realize high efficient machining.

● New developed special edge profile realized multi-functional performance of side milling, slot milling and plunging approaches on carbon steels.

● Long time stable machining is realized by adopting MUGEN COATING.

● Total 62 sizes, some sizes line up with L/D = 2 or 3.

Click here for size variations and recommend milling conditions.

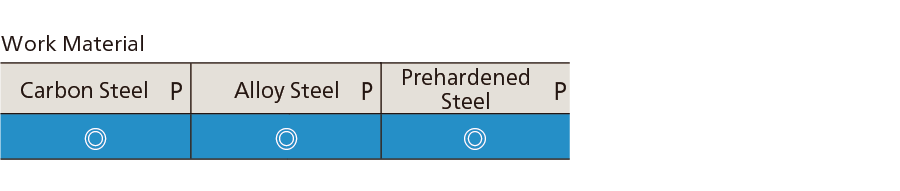

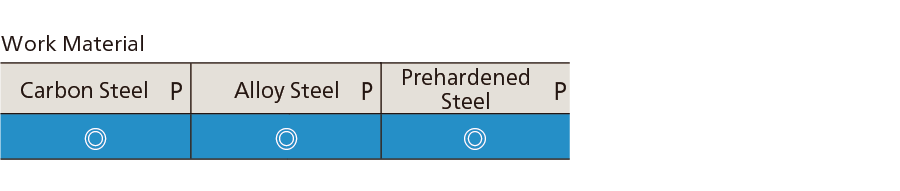

● Unequal flute spacing, unequal helix angle and high rigid end profile design to minimize chatter realize high efficient machining.

● New developed special edge profile realized multi-functional performance of side milling, slot milling and plunging approaches on carbon steels.

● Long time stable machining is realized by adopting MUGEN COATING.

● Long neck type prevent interference with work material, the Under Neck length lined up with L/D = 3 to 5.

Click here for size variations and recommend milling conditions.

Features

Machining case

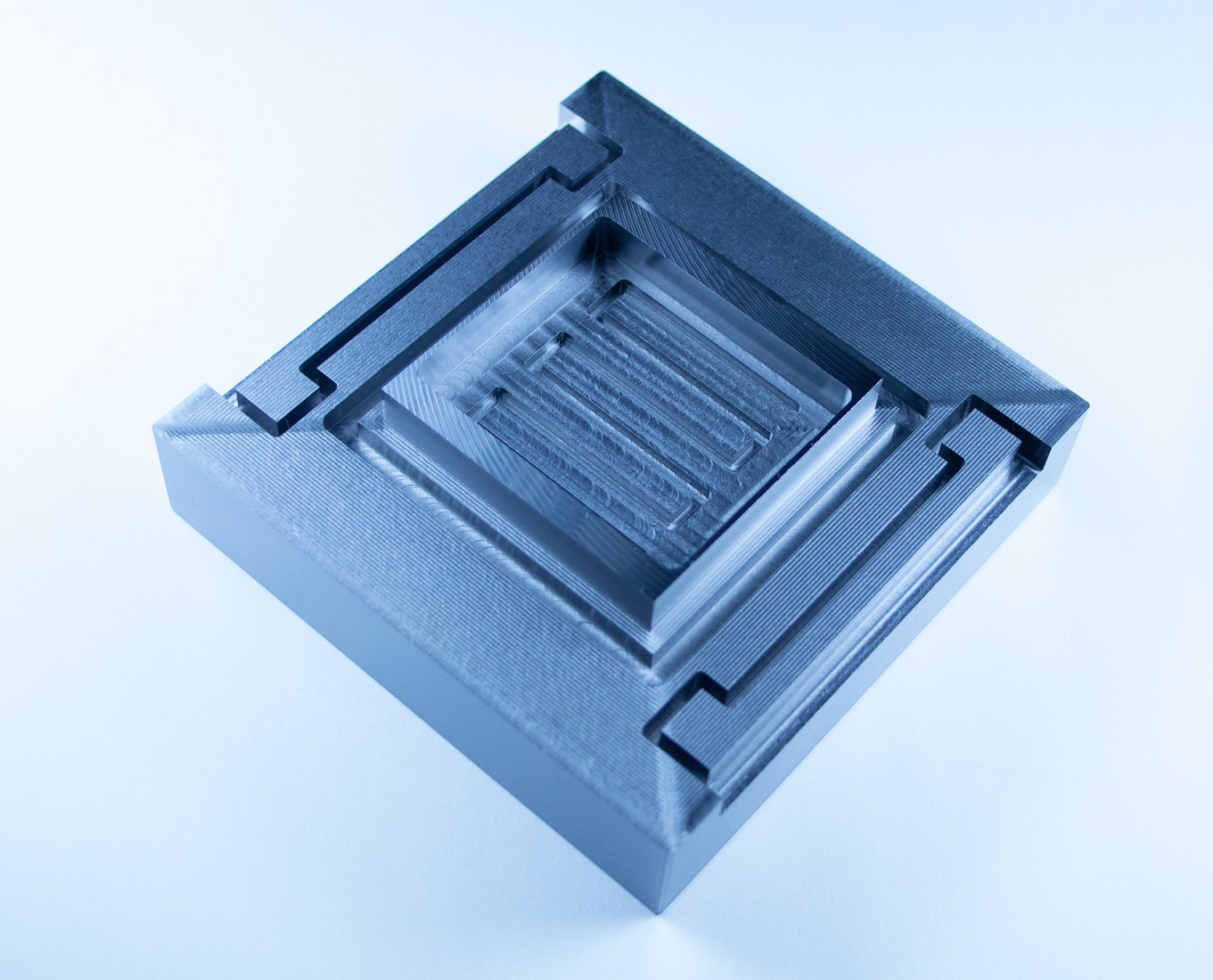

MSCZ440 Carbon Steels (S50C), high efficiency machining

Work size: 100 × 100 × 30 mm, S50C, high eifficiency.

For details, please check here.

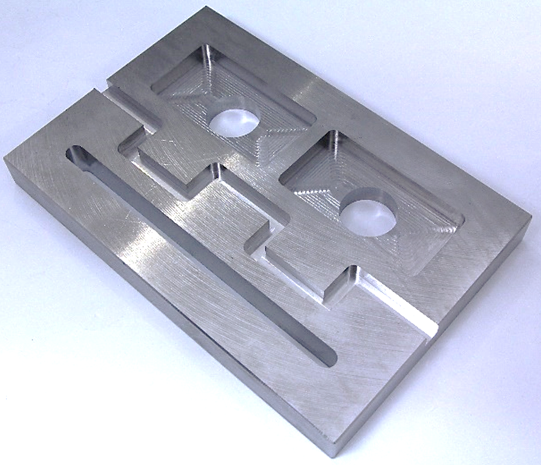

MSCZ440 High efficient machining

Work size: 150 × 100 mm, SCM415, slotting and pocket with high eifficiency.

For details, please check here.