Product

High efficient "Z" end mill series

MUGEN COATING PREMIUM

4-Flute High Efficient “Z” End Mill for Stainless SteelsReleased in November, 2019.

MUGEN COATING

4-Flute High Efficient "Z" End Mill for Carbon SteelsReleased in December, 2019.

MUGEN COATING PREMIUM

4-Flute High Efficient “Z” End Mill for Stainless Steels

Redefinition of stainless steels machining!

Minimizing chatter and shorten machining time!

●Regular type MSUSZ440

Dia.:φ1~6

Total 62 size, some sizes lined up with L/D=2 or 3.

For details, pleaseclick

●Long neck type MSUSZ440-LN

Long neck type for prevention of interference with work material.

Dia.:φ1~6

Total 33 sizes

Effective length lined up with L/D=3 to 5.

For details, pleaseclick

MUGEN COATING

4-Flute High Efficient "Z" End Mill for Carbon Steels

Eventually, it’s coming!

High efficient “Z” end mill specialized for carbon steels

●Regular type MSCZ440

Dia.:φ1~6

Total 62 size, some sizes lined up with L/D=2 or 3.

For details, pleaseclick

●Long neck type MSCZ440-LN

Long neck type for prevention of interference with work material.

Dia.:φ1~6

Total 33 sizes

Effective length lined up with L/D=3 to 5.

For details, pleaseclick

Four techniques of high efficient machining.

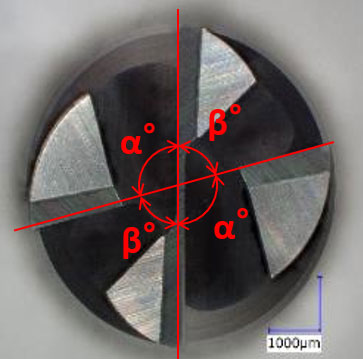

●Adopted unequal flute spacing and unequal helix angle

By adopting unequal flute spacing and unequal helix angle to prevent chattering produced by sympathetic vibration.

Enhanced tool life and machining surface quality.

Unequal Flute Spacing

Unequal Helix Angle

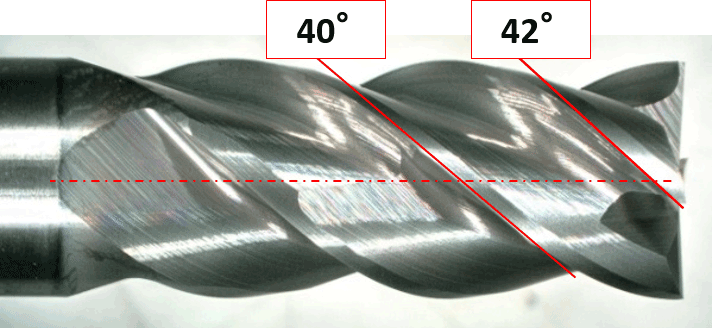

●Enhanced peripheral cutting edge

Developed a stronger flute to resist high load machining, even with small-diameter φ1 can also realize high efficient machining.

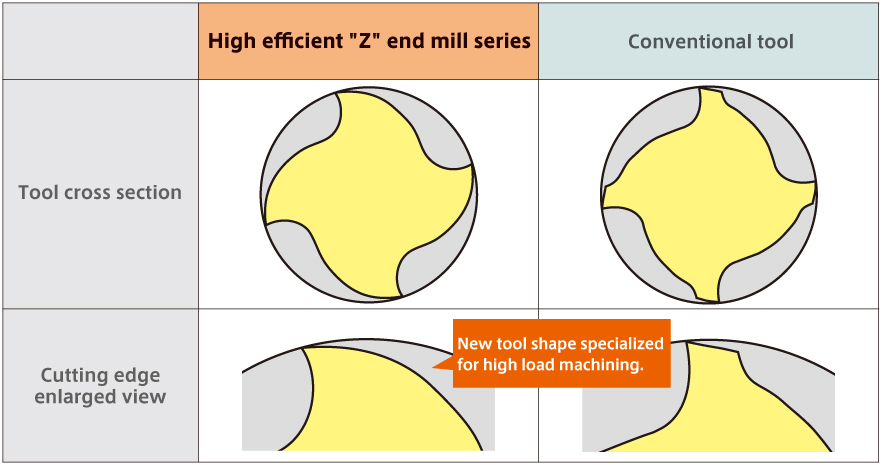

●Specialized flute shape!

A large chip pocket with improved chip removal ability at the front flute, and a high rigidity design with a strong core at the end part realized high efficiency machining.

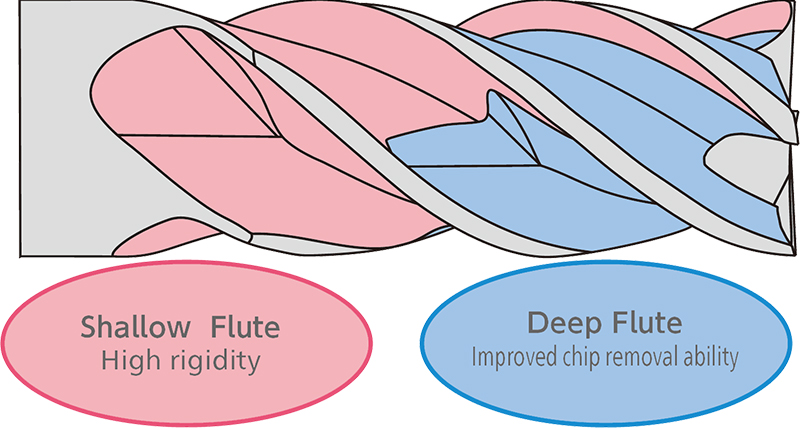

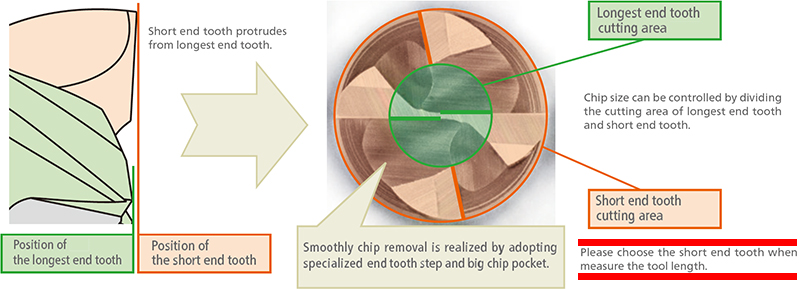

●Chip control by the step of the end tooth

By design the step of the longest end tooth, short end tooth, and big chip pocket, divide each cutting area when drilling helped chip removal smoothly.

Leaflet

MUGEN COATING PREMIUM

4-Flute High Efficient “Z” End Mill for Stainless Steels

MUGEN COATING

4-Flute High Efficient "Z" End Mill for Carbon Steels

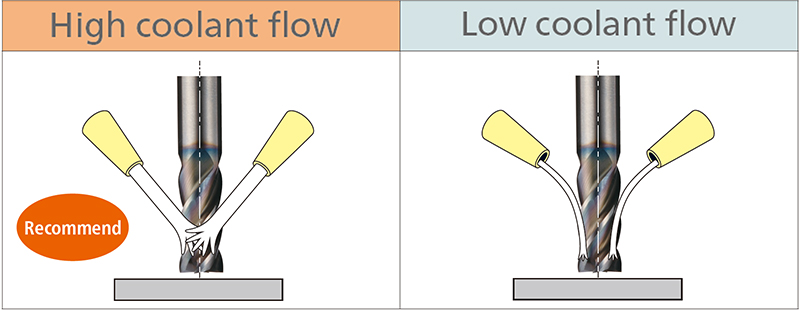

Machining points Coolant

While drilling approach…

Please increasing the coolant flow rate and pressure as much as possible, and supply it sufficiently to the machining point and flute.

Please change the depth of cut or feed when chips could not remove smoothly during drilling.

Please be noted there would be a possible tool chipping or breakage when the chip removal is insufficient.

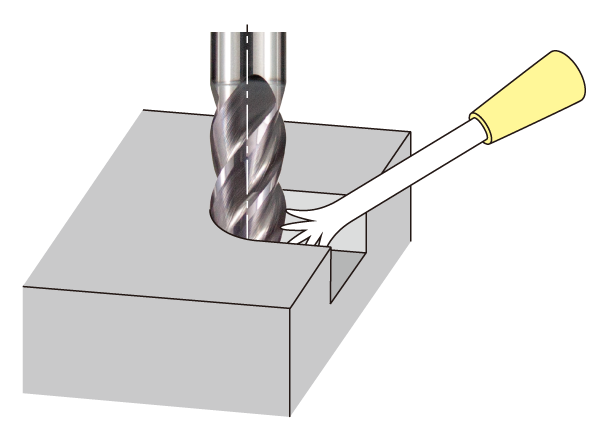

While slotting…

Supply coolant properiy by chasing the end mill.

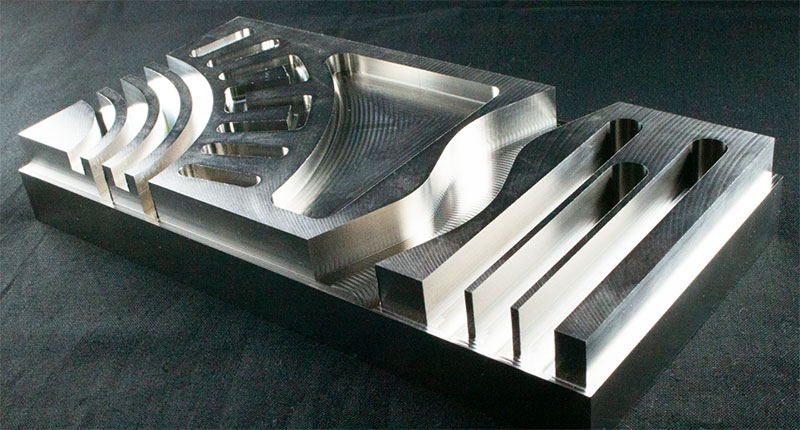

Cutting example

High Efficient Machining Example for Stainless Steels (SUS304)

Work size: 200×100mm (Cutting depth: 12mm) Total 12.5 minutes for high efficient machining!

For details, pleaseclick

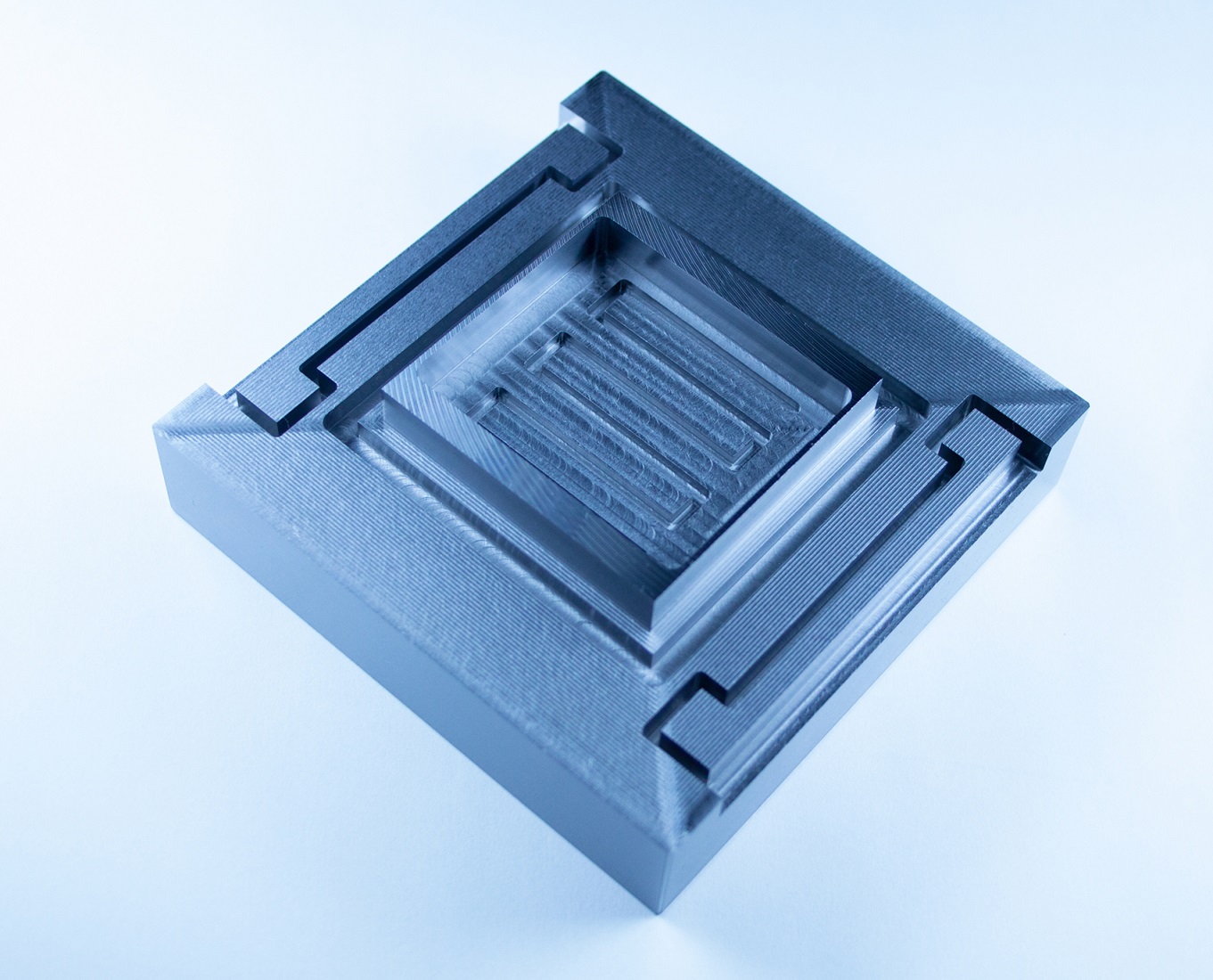

MSCZ440 (S50C) High efficient milling sample

Work size:100×100×30mm(Cutting depth:14mm) Total 23 minutes for high efficient machining!

For details, pleaseclick