Product

MUGEN COATING PREMIUM Plus

4-Flute Long Neck Corner Radius End Mill with short shank for Hardened Steel and High accuracy cutting

Suitable for shrink fit holder

MHRSH430RSF

Product

MUGEN COATING PREMIUM Plus

4-Flute Long Neck Corner Radius End Mill with short shank

for Hardened Steel and High accuracy cutting

Suitable for shrink

fit holder

MHRSH430RSF

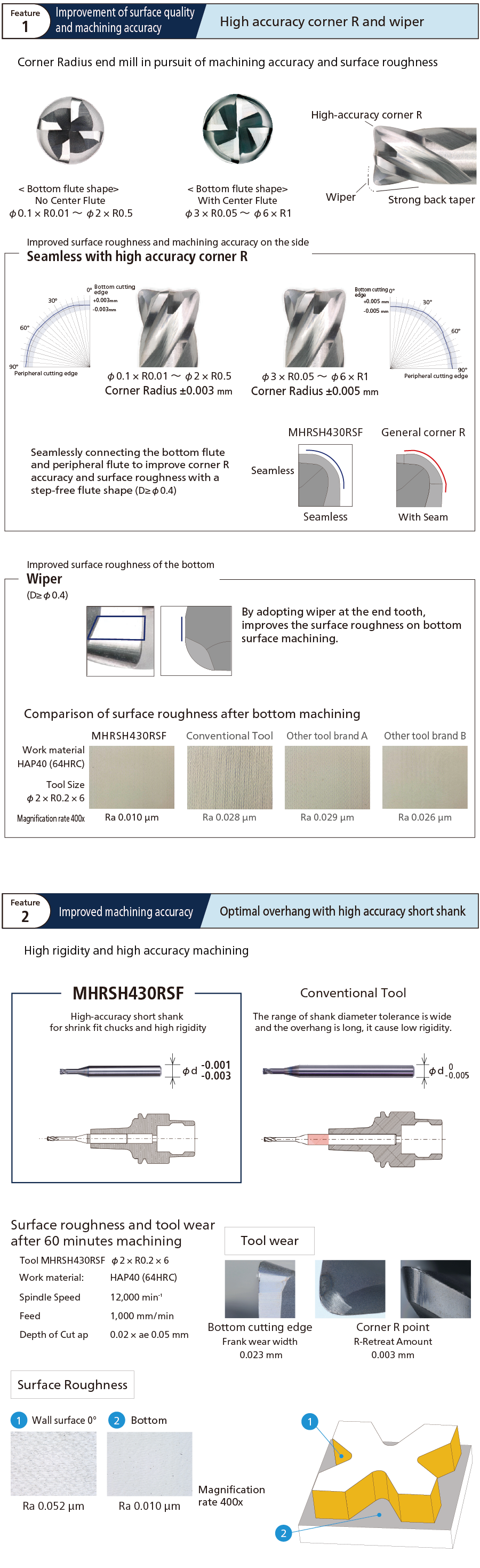

● MUGEN COATING PREMIUM Plus for hardened steels with strong back taper reduce chattering to realize long tool life and excellent finishing surface.

● 4-flute end mill for high efficiency machining.

● 4-flute from φ0.1 to φ6 Total 205 sizes.

Features

Machining case

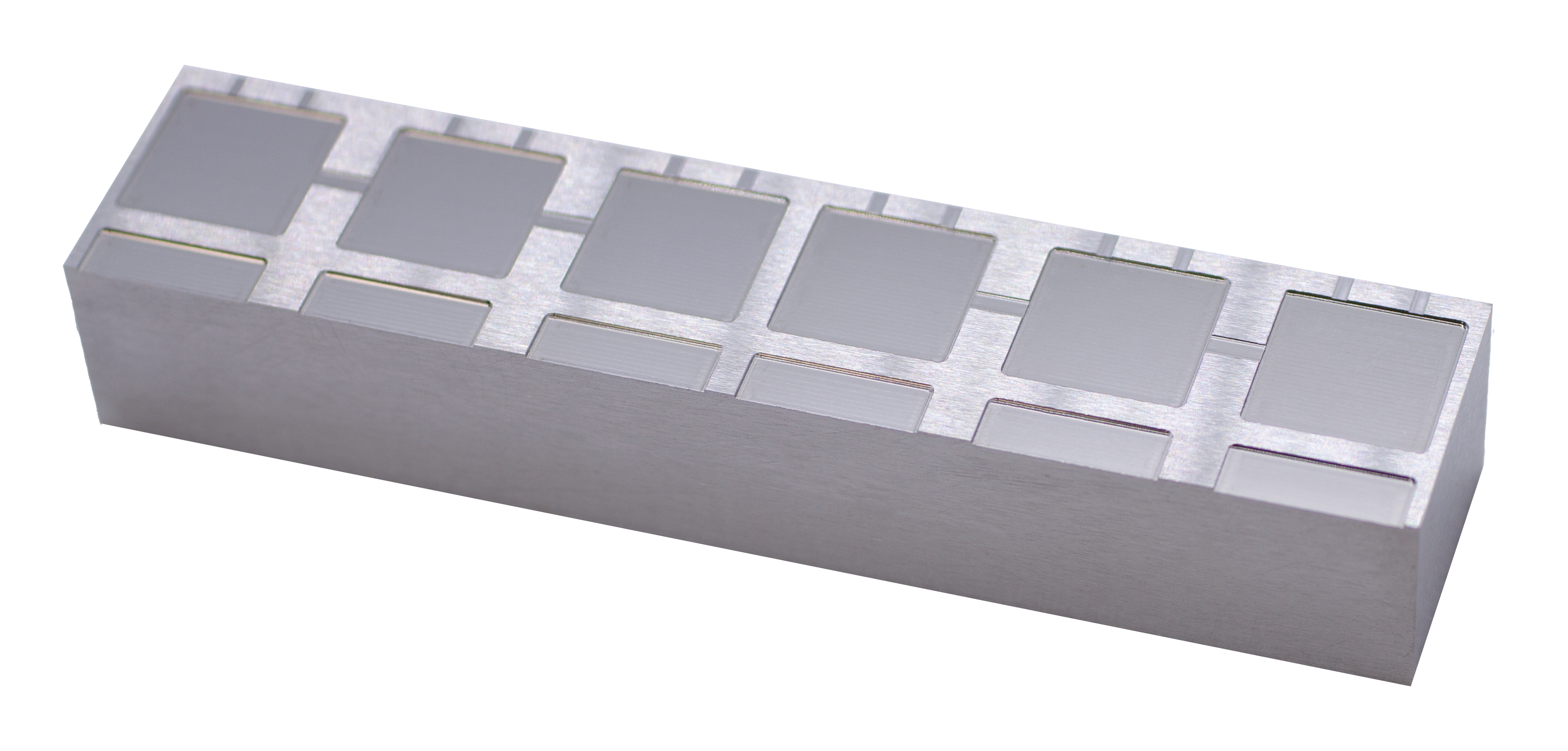

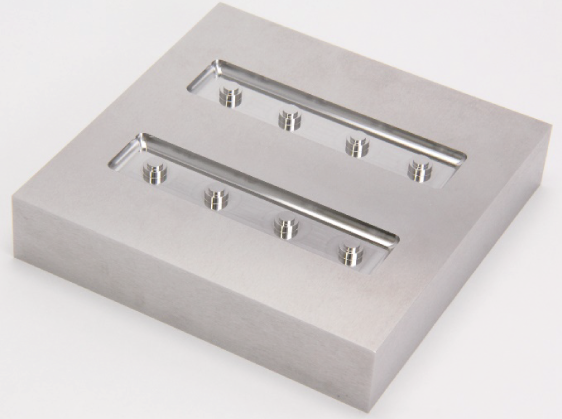

Sealed mold

Work size: 20×90×15 mm, long life and high precision machining on VANADIS23 by using small diameter size.

For details, please click here.

Gear mold

Work size: 50×50 mm, a machining example that maintains high accuracy even during long machining with MUGEN COATING PREMIUM Plus that increases tool life and high-precision tool design.

For details, please click here.

Two stage pocket mold

Work size: 100×100×25 mm, a machining example that achieved stable machining with little difference in machining accuracy between the initial and final stages of hardened steel.

For details, please click here.

Press Die for Auto Parts

Work size: 100×100×40mm, machining on HAP40 (64HRC) by MHRSH430RSF.

For details, please click.

Forging Die Model

Work size: 85×25×15mm, machining on SKD55(64HRC) by MHRSH430RSF.

For details, please click.

Forging Die Model (2 pieces)

Work size: 100×100mm, machining on SKH51(62HRC) by MHRSH430RSF.

For details, please click.