Technology

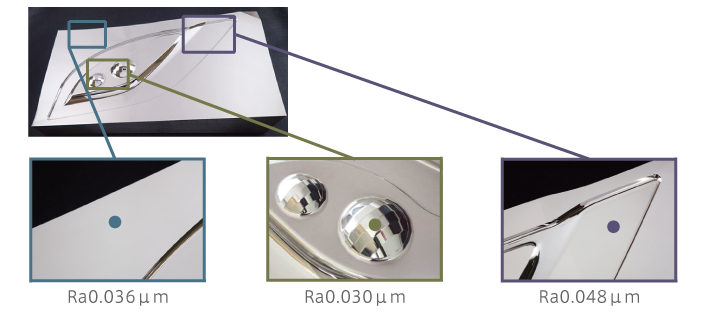

Mirror Finishing

STAVAX / 52HRC

PCDRB / PCD Ball End Mill

Work size: 200×100(mm)

Material : STAVAX 52HRC

Cutting time: 94hr 50min.

The Roughness is less than Ra0.05µm.

Finished surface looks "smooth, even and shiny" such as the mirror surface.

Used MRBH230 for roughing and SSPB220 for Semi-finishing.

Tool

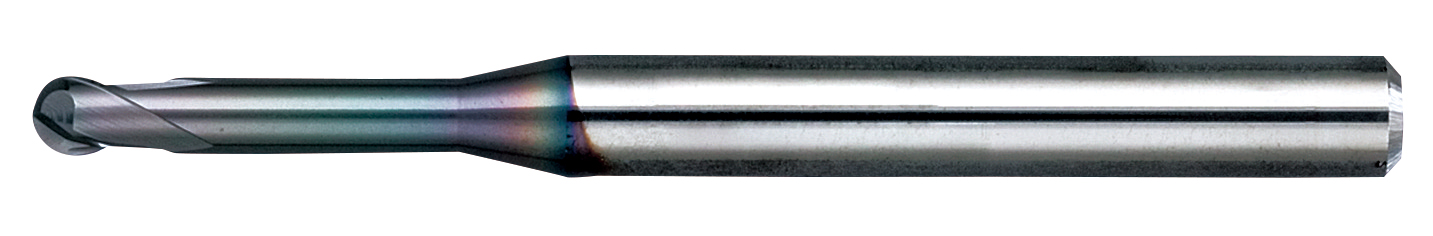

PCDRB

•Unique tool geometry makes stable surface.

•Polish-less machining become reality by nano-level roughness on profiling finish.

•Upgraded tool edge design makes stable high quality surface.

SSPB220

•Adopted spiral ball shape to improve sharpness of cutting edge.

•Adopted cutting edge shape to improve the chipping resistance of cutting edge.

•When peripheral cutting edge makes contact with cutting surface, vibration occurs by an increase in cutting resistance and it affects tool life and cutting surface quality. The influence can be reduced by adoption of the strong back taper shape.

•Enlarged standard tool size up to R3 to extend application range.

MRBH230

•MUGEN-COATING PREMIUM for hardened steels and unique new design excel in chipping prevention and resolves chattering to realize excellent finished surface.

•Applicable for hardened steels up to 68HRC.

•Total 190 sizes!

Cutting Condition

| Cutting Process | 1st Roughing | 2nd Roughing | 3rd Roughing | Semi-finishing | Finishing |

| Tool | MRBH230 R3×10 |

MRBH230 R2×8 |

MRBH230 R1×6 |

SSPB220 R1×5 |

PCDRB R1×5 |

| Spindle Feed (min-1) |

15,000 | 15,000 | 20,000 | 45,000 | 45,000 |

| Feed (mm/min) |

2,500 | 2,000 | 1,500 | 1,200 | 1,200 |

| Depth of Cut ap×ae(mm) |

0.3×2.0 | 0.2×1.0 | 0.05×0.05 | 0.02×0.02 | 0.005×0.005 |

| Stock (mm) |

0.15 | 0.07 | 0.025 | 0.005 | - |

| Coolant | Water-insoluble fluid | ||||

| Cutting Time | 8hr18min | 1hr42min | 5hr7min | 15hr58min | 63hr45min |

Comment

CBN tool that is proper to cutting high hard metals is used for semi-finishing process for stock equalization. Furthermore, PCDRB is used for finishing process which adopted PCD (sintered diamond) and unique cutting edge. CBN tool and PCD tool combination realized mirror like surface quality without polishing.

Related Movie

- Unique tool geometry makes stable surface.

- Upgraded tool edge design makes stable high quality.

- Polish-less machining become reality by nano-level roughness on profiling finish.