Technology

Hexalobular Punch Model

HAP40 / 65HRC

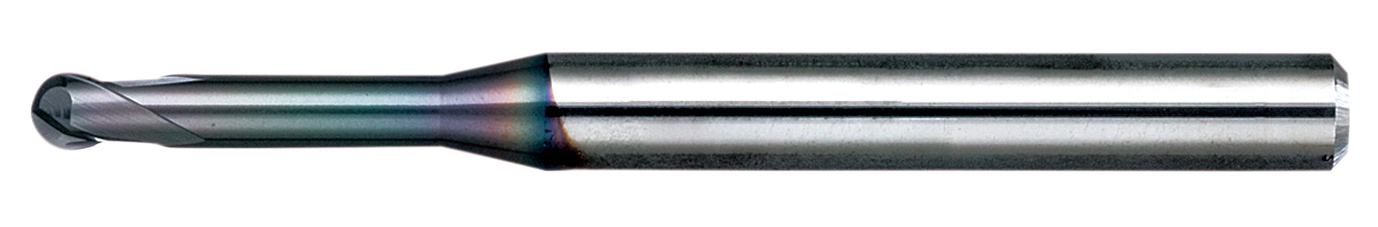

SSPB220 / CBN Spiral Ball End Mill

Work size : Φ25 (Depth 30mm)

Material : HAP40 65HRC

Cutting time: 4hr 36min

SSPB220 has expanded size range up to R3 since November 2016.

Realized high quality surface by adopting spiral ball shape which improves sharpness of cutting edge and by strong back-taper shape to reduce chattering.

Tool

SSPB220

•Adopted spiral ball shape to improve sharpness of cutting edge.

•Adopted cutting edge shape to improve the chipping resistance of cutting edge.

•When peripheral cutting edge makes contact with cutting surface, vibration occurs by an increase in cutting resistance and it affects tool life and cutting surface quality. The influence can be reduced by adoption of the strong back taper shape.

•Enlarged standard tool size up to R3 to extend application range.

MRBH230

•MUGEN-COATING PREMIUM for hardened steels and unique new design excel in chipping prevention and resolves chattering to realize excellent finished surface.

•Applicable for hardened steels up to 68HRC.

•Total 190 sizes!

Cutting Condition

| Cutting process | Roughing | Semi-finishing | Finishing |

| Tool | MRBH230 R3×20 |

MRBH230 R3×20 |

SSPB220 R3×18 |

| Spindle feed (min-1) |

6,000 | 6,000 | 6,000 |

| Feed (mm/min) |

1,000 | 800 | 600 |

| Depth of cut ap×ae(mm) |

0.15×0.8 | 0.05×0.08 | 0.05×0.05 |

| Coolant | Oil mist | ||

| Cutting time | 1hr43min | 55min | 1hr58min |

Comment

The difference in dimension is +0.006mm and the roughness is Rz1.355μm.

Even after 6 more works, precision is keeping the quality as difference +0.008mm and roughness Rz1.355μm.

Related Movie

- Adopted cutting edge shape to improve the chipping resistance of cutting edge.

- Enlarged standard tool size up to R3 to extend application range.