Technology

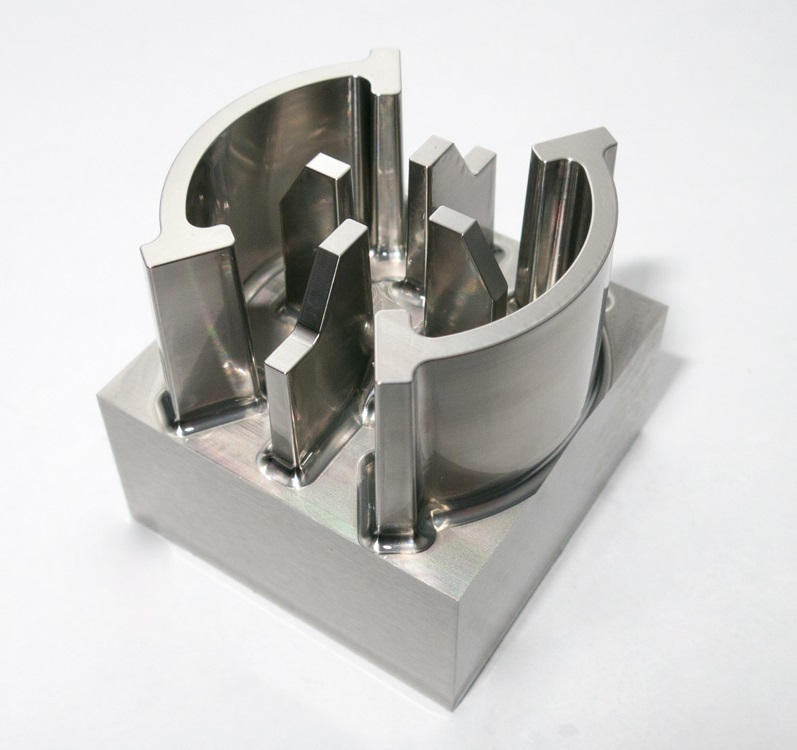

Deep Milling Model

ELMAX / 60HRC

SSPBTN220 / CBN Long Taper Neck Ball End Mill

Work size : 30x30mm (cutting depth 15mm)

Material : ELMAX 60HRC

Cutting time: 18hr 9min.

High efficiency and highly precise processing are enabled by choosing a long taper neck type: SSPBTN220 to a processing shape.

Tool

SSPBTN220

•To realize more rigid, CBN Long Neck Ball End Mill with taper neck are adopted.

•Both efficiency and accuracy are increasing by taper neck design and spiral ball shape with improved sharpness in finish processing on deep milling.

MRBTNH345

•Higher rigidity brought by taper neck than existing long neck.

•MUGEN-COATING PREMIUM because of high heat resistance, realized long tool life for hardened steels.

•High effective machining achieved by NS original 3-flute design.

Cutting Condition

| Cutting Process | Roughing* | Stock removal | Semi-finishing | Finishing |

| Tool | MRBTNH345 R1.5×1°×15 |

MRBTNH345 R1.5×1°×16 |

SSPBTN220 R1×1°×16 |

|

| Spindle speed (min-1) |

15,000 | 10,000 | 10,000 | 16,000 |

| Feed (mm/min) |

1,600 | 1,000 | 1,000 | 800 |

| Depth of cut ap×ae(mm) |

0.1×0.3 | 0.1×0.1 | ap0.05 | ap0.01 |

| Stock (mm) |

0.06 | 0.06 | 0.01 | - |

| Coolant | Oil mist | |||

| Cutting time | 7hr4min | 22min | 1hr56min | 8hr47min |

* 2 end mills used for roughing process

Comment

Surface roughness is from Rz0.423μm to Rz1.086μm.

Difference of dimension is delivered to the range from +0.004mm to +0.006mm, and even the deep milling for high hard metal can keep precision.

Furthermore, the tool condition is available continuously because tool R wear is only 2μm.