Technology

DVD Case Model STAVAX / 52HRC MHRH430R / Long Neck Radius End Mill for Hardened Steels

Work size:150×150(mm)

Material: STAVAX 52HRC

Cutting Time: 12 hr 38 min

Adopting MUGEN-COATING PREMIUM, MHRH430R realizes stable roughness of surface in direct milling to stainless-type hardened steels.

Tool

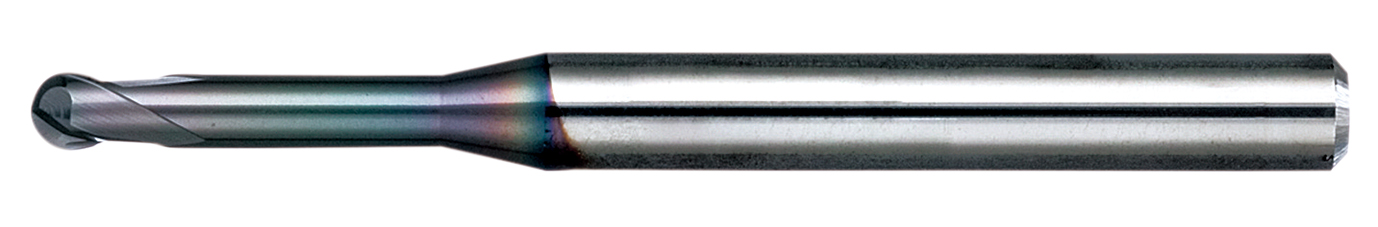

MHRH430R

•MUGEN-COATING PREMIUM for hardened steels and unique new design excel in chipping prevention and resolve chattering to realize excellent finished surface.

•4 flutes end mill for higher efficiency.

Total 326 sizes.

MRBH230

•MUGEN-COATING PREMIUM for hardened steels and unique new design excel in chipping prevention and resolves chattering to realize excellent finished surface.

•Applicable for hardened steels up to 68HRC.

•Total 190 sizes.

Cutting Condition

| Cutting process | Roughing | Semi-finishing | Finishing | |

| Side | Bottom | |||

| Tool | MHRH430R φ6×R0.5×24 |

MRBH230 R1×8 |

MHRH430R φ2×R0.5×8 |

|

| Spindle speed (min-1) |

6,000 | 20,000 | 40,000 | |

| Feed (mm/min) |

6,000 | 2,000 | 3,000 | 2,000 |

| Depth of cut ap×ae(mm) |

0.15×1.5 | 0.2×0.3 | 0.02×0.01 | 0.01×0.03 |

| Stock (mm) |

0.1 | 0.01 | - | |

| Coolant | Oil mist | |||

| Cutting time | 1 hr 40 min | 1 hr 58 min | 1 hr 30 min | 7 hr 30min |

Comment

Utilizing MUGEN-COATING PREMIUM series end mill, aimed and realized for stable machining environment, deflection reduce, roughness improvement and shiny finished surface in direct milling to stainless-type hardened steels.