Technology

Valve Body Model DH31-S / 48HRC MRBTNH345 / Long Taper Neck Ball End Mill

Work size: 50×50×50(mm)

(Cutting Depth: 30mm)

Material: DH31-S 48HRC

Cutting time: 10 hr 47 min

MRBTNH345 improved higher rigidity with taper neck design than existing long neck type.

Tool

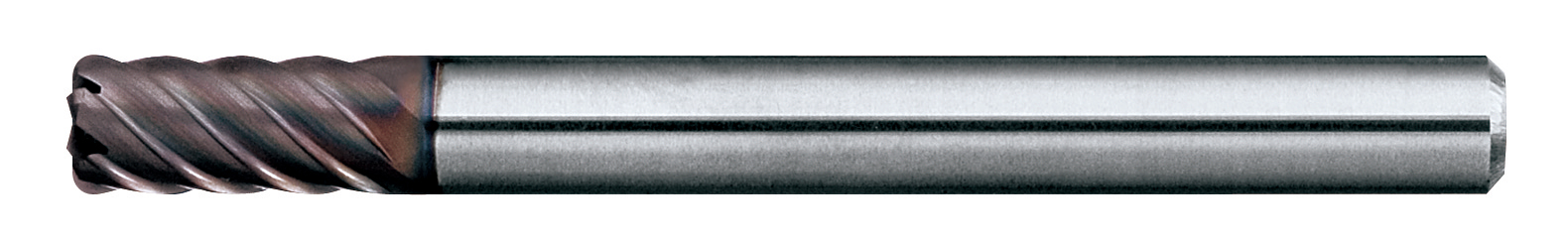

MRBTNH345

•Higher rigidity brought by taper neck than existing long neck.

•MUGEN-COATING PREMIUM because of high heat resistance, realized long tool life for hardened steels.

•High effective machining achieved by NS original 3-flute design.

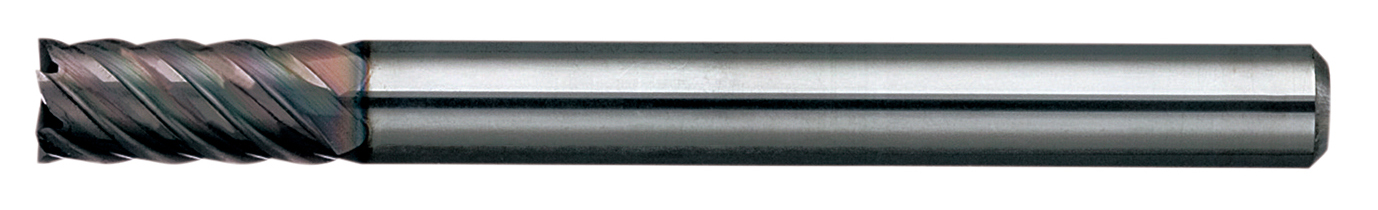

MHDH645R

•Realized stably long tool life against high hardened steels (48~65HRC).

•Corner radius to prevent flute chipping, and high helix angle for cutting sharpness.

MHDH645

•L/D=2 and L/D=3 length of cut selection.

•Realized stably long tool life against high hardened steels (48~65HRC).

•Improved milling deflection and accuracy by advanced flute design.

Cutting Condition

| Cutting process | Pre-roughing | Roughing | Semi-roughing | 1st Semi-finishing | 2nd Semi- finishing | Finishing | |

| Side | Bottom | ||||||

| Tool | MHDH645 φ6×18 |

MHDH645R φ6×R1×12 |

MRBTNH345 R1.5×1°×30 |

MRBTNH345 R1×1°×20 |

MRBTNH345 R1×1°×30 |

MRBTNH345 R1×1°×30 |

|

| Spindle speed (min-1) |

9,000 | 6,000 | 10,000 | 10,000 | 10,000 | 6,000 | |

| Feed (mm/min) |

3,000 | 3,000 | 1,600 | 1,000 | 1,000 | 800 | |

| Depth of cut ap×ae(mm) |

9×0.2 | 0.1×4 | ap0.1 | ap0.1 | ap0.05 | 0.15×0.05 | 0.05×0.1 |

| Stock (mm) |

0.2 | 0.2 | 0.2 | 0.05 | 0.05 | - | |

| Coolant | Oil mist | ||||||

| Cutting time | 35 min | 15 min | 1 hr 17 min | 2 hr 6 min | 3 hr 40 min | 2 hr 54 min | |

Comment

Stable milling quality on side and bottom surface has realized with taper neck design which is applicable for high efficient 3 dimensional milling and MUGEN-COATING PREMIUM for prolong tool life.