Technology

Direct Milling of Hardened Steel PD613 / 60HRC MHDH445/645 / Square End Mill for Hardened Steel

Work size: 120×80(mm)

Material: PD613 60HRC

Cutting Time: 1hr 31min

By adopting MUGEN-COATING PREMIUM, MHDH445/645 provides stable milling to hardened steels.

Tool

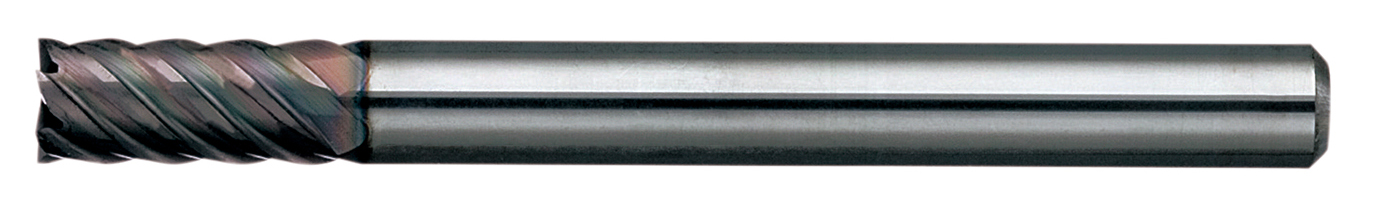

MHDH645

•L/D=2 and L/D=3 length of cut selection.

•Realized stably long tool life against high hardened steels (48~65HRC).

•Improved milling deflection and accuracy by advanced flute design.

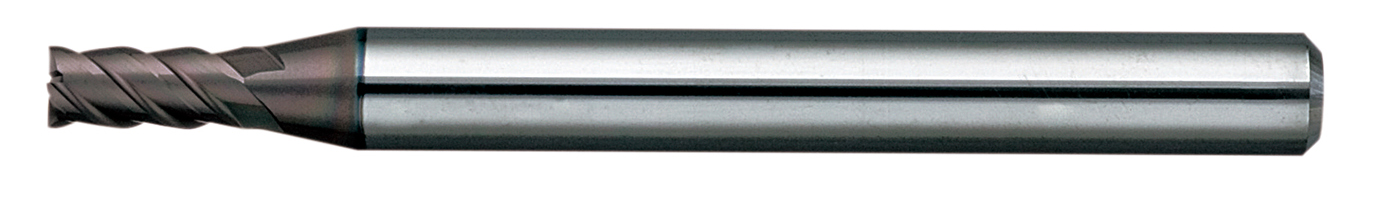

MHDH445

•Realized stably long tool life against high hardened steels (48~65HRC).

•Improved milling deflection and accuracy by advanced flute design.

Cutting Conditions

Machined by MHDH645

| Cutting process | Pre-roughing | Roughing | Finishing | ||

| Helical | Side | Slotting | |||

| Tool | MHDH645 φ10×20 |

MHDH645 φ6×12 |

MHDH645 φ6×12 |

||

| Spindle speed (min-1) |

3,200 | 5,000 | 5,000 | ||

| Feed (mm/min) |

1,600 | 350 | 2,000 | 600 | 600 |

| Depth of cut ap×ae(mm) |

20×0.3 | ap0.15 | 12×0.2 | ap0.15 | 8~12×0.01 |

| Coolant | Oil mist | ||||

| Cutting Time | 12 min | 3 min | 15 min | 20 min | 5 min |

Machined by MHDH445

| Cutting process | Roughing | Finishing |

| Slotting | Side | |

| Tool | MHDH445 φ3 | |

| Spindle speed (min-1) |

10,000 | |

| Feed (mm/min) |

500 | 350 |

| Depth of cut ap×ae(mm) |

ap0.05 | 1.5×0.01 |

| Coolant | Oil mist | |

| Cutting Time | 36 min | |

Comment

Approached the central circle part by helical processing and developed it by lateral processing, milling deflection is under 3 μm.

Both end slots are processed with MHDH445 φ3. Whole process of direct milling to block of hardened steel was finished in 1 hour 31 minutes.