Technology

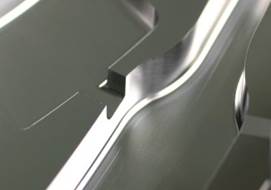

Mouse Cavity Model

STAVAX / 52HRC

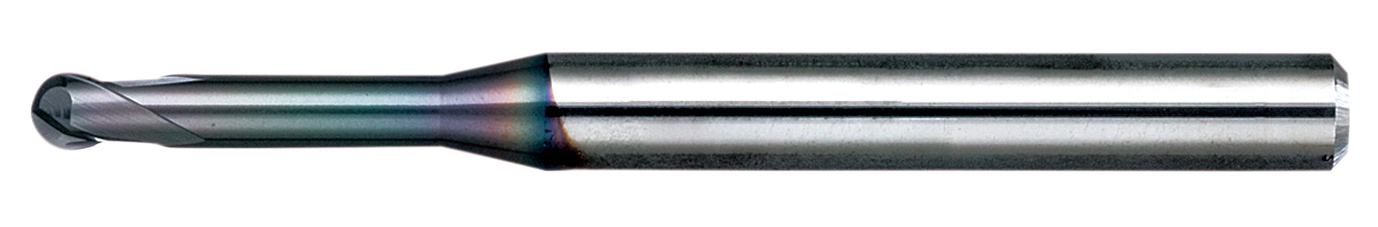

MSBH230 and MRBH230 / Ball End Mill and Long Neck Ball End Mill for Hardened Steels

Work size: 135×95(mm)

Material: STAVAX 52HRC

Cutting time: 13 hr 17 min (except roughing)

MSBH230/MRBH230, small diameter end mills, obtained a stable cutting surface even if processing to high hardness materials for a long time, at slotting also.

Tool

MRBH230

•MUGEN-COATING PREMIUM for hardened steels and unique new design excel in chipping prevention and resolves chattering to realize excellent finished surface.

•Applicable for hardened steels up to 68HRC.

•Total 190 sizes!

MSBH230

•Standard ball end mill for hardened steels and suitable for finishing process.

•Applicable for hardened steels up to 68HRC.

Cutting Conditions

| Cutting process | Parting face part finishing | 1st Main part finishing | 2nd Main part finishing | Slot finishing |

| Tool | MSBH230 R3 |

MRBH230 R1×6 |

MRBH230 R0.5×6 |

MRBH230 R0.3×4 |

| Spindle speed (min-1) |

12,000 | 18,000 | 18,000 | 18,000 |

| Feed (mm/min) |

1,120 | 720 | 720 | 300 |

| Depth of cut Rmax(mm) |

pf 0.12 | pf 0.05 | pf 0.02 | ap0.01 |

| Stock (mm) |

0.05 | 0.03 | 0.025 | 0.015 |

| Coolant | Oil mist | |||

| Cutting time | 2 hr 20 min | 6 hr 4 min | 2 hr 43 min | 2 hr 10 min |

pf: pick feed.

Comment

* Parting line part finishing

Surface roughness: Rz 0.909 μm

Wear of MSBH230 R3: 0.008 mm.

* 1st Main part finishing

Surface roughness: Rz 1.492 μm

Wear of MRBH230 R1 × 6: 0.008 mm.

* 2nd Main part finishing

Surface roughness: Rz 0.607μm

Wear of MRBH230 R0.5 × 6: 0.01 mm.

* Slot finishing

Incline 1° and depth 4 mm.

Wear of MRBH230 R0.3 × 4: 0.008 mm.

Realized stable milling at small diameter rib slotting of L/D=6.6