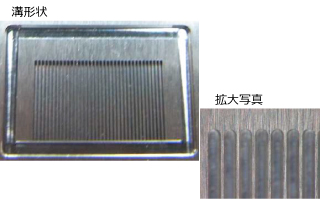

Technology

Precise Milling Model

SSR200 / CBN Super Speed Radius End Mill

PD613 / 60HRC

Work size: 30×30(mm)

Material: PD613 60HRC

Cutting time: 7 hr 57 min (only finishing)

Even with very small diameter in Φ 0.2, CBN end mill realize providing stable surface quality and high accuracy for long time milling on high hard materials.

Tool

SSR200

•Realized high efficient machining with radius flute along with excellent wear resistance of CBN.

•Realized excellent surface roughness by introducing smooth tangent on all over flute.

•Applicable for work materials from tempered steel to hardened steel (up to 68HRC).

•Lineup expansion from Dia.0.1 mm. 172sizes in total.

Cutting Condtions

Slot part

| Cutting process | Slotting to Z-0.03 |

Slotting to Z-0.5 |

| Tool | SSR200 Φ0.2×R0.02×0.5 | |

| Spindle speed (min-1) |

40,000 | |

| Feed (mm/min) |

100 | 300 |

| Depth of cut ap×ae(mm) |

ap0.001 | ap0.003 |

| Coolant | Oil mist | |

| Cutting time | 1 hr 8 min | 2 hr 19 min |

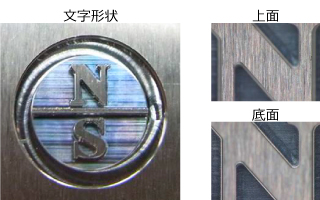

NS logo part

| Cutting process | Side finishing | Bottom finishing |

| Tool | SSR200 Φ0.2×R0.02×0.5 | |

| Spindle speed (min-1) |

40,000 | |

| Feed (mm/min) |

300 | |

| Depth of cut ap×ae(mm) |

0.001×0.005 | 0.005×0.005 |

| Coolant | Oil mist | |

| Cutting time (2D per hole) |

1 hr 55 min | 20 min |

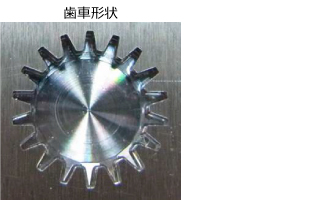

Gear part

| Cutting process | Side finishing | Bottom finishing |

| Tool/font> | SSR200 Φ0.2×R0.02×1 | |

| Spindle speed (min-1) |

40,000 | |

| Feed (mm/min) |

200 | |

| Depth of cut ap×ae(mm) |

0.003×0.005 | 0.005×0.005 |

| Coolant | Oil mist | |

| Cutting time | 1 hr 45 min | 30 min |

Comment

Slot size: W0.21 mm× D0.5 mm× L5 mm

Small cutting pitch condition on initial milling to realize stable machining accuracy to 0.5mm depth.

36 grooves by 1 end mill.

Magnified photo of NS logo part.

As shown in the figure, target tolerance was +0.001 mm.

Outer periphery of gear was tolerance -0.004 mm to the target and bottom surface roughness was Rz 0.25 μm.