Technology

DRB230 Tough-Pitch Copper Comparison of tool life

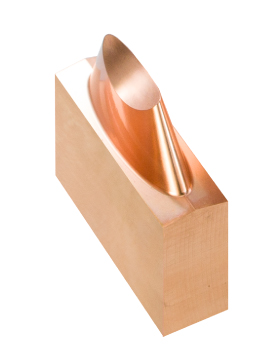

Material : Tough-Pitch Copper

Work Size 11 × 40(mm)

Cutting depth 15.2mm (1pc)

Cutting time : 1hr 45min (1pc)

Tool

DRB230

●Long neck ball end mill specialized for machining copper alloy.

●Sharp edge shearing ability and DLC coating realized high quality and stable a long life machining.

●Machining copper tungsten electrodes is also effective.

Cutting condition

| Process | Roughing | Semi-finishing | Finishing |

| Tool | DRB230 R0.5×4 |

||

| Spindle speed (min-1) |

40,000 | 30,000 | |

| Feed (mm/min) |

2,400 | 2,000 | 1,500 |

| Depth of cut ap×ae(mm) |

0.2×0.4 | 0.05×0.05 | 0.03×0.03 |

| Stock (mm) |

0.07 | 0.03 | - |

| Coolant | Water-insoluble fluid | ||

| Cutting time | 55min | 50min | |

Comment

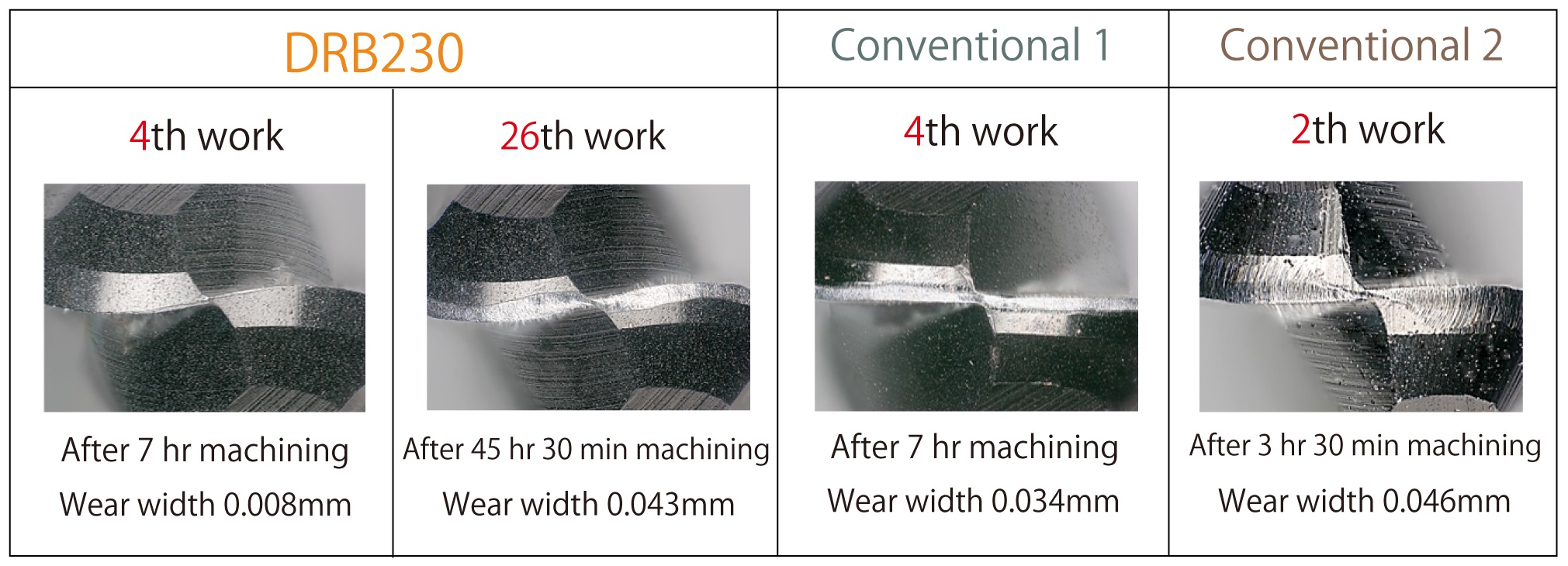

By using same tool size to compare tool wear and surface roughness with conventional products.

In this machining, DRB230 approximated 6 to 7 times tool life comparing to conventional products.

Machining from roughness to finishing by using 1 end mill.

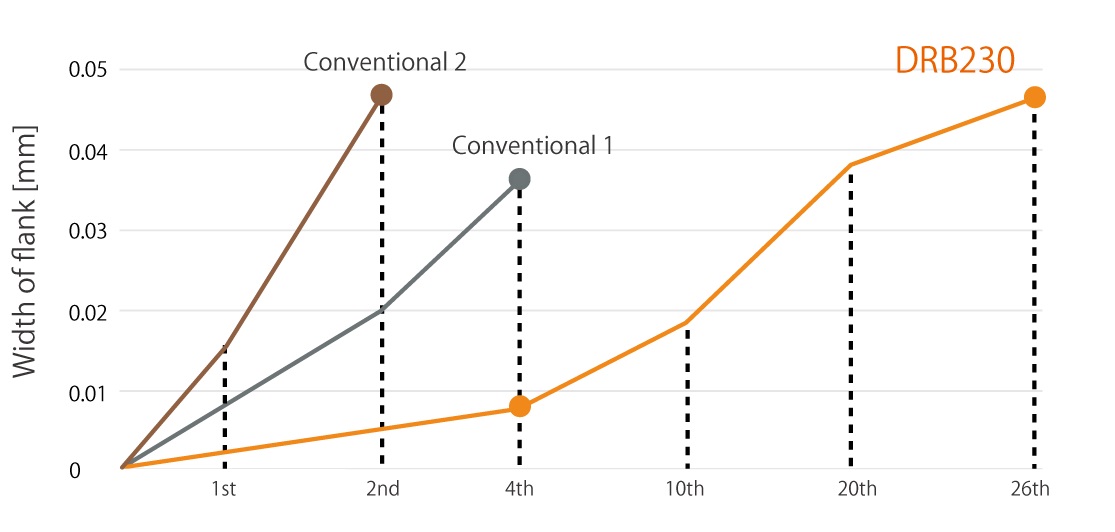

Comparison of tool wear

For image point, please see the graph below.

Condition of edge profile

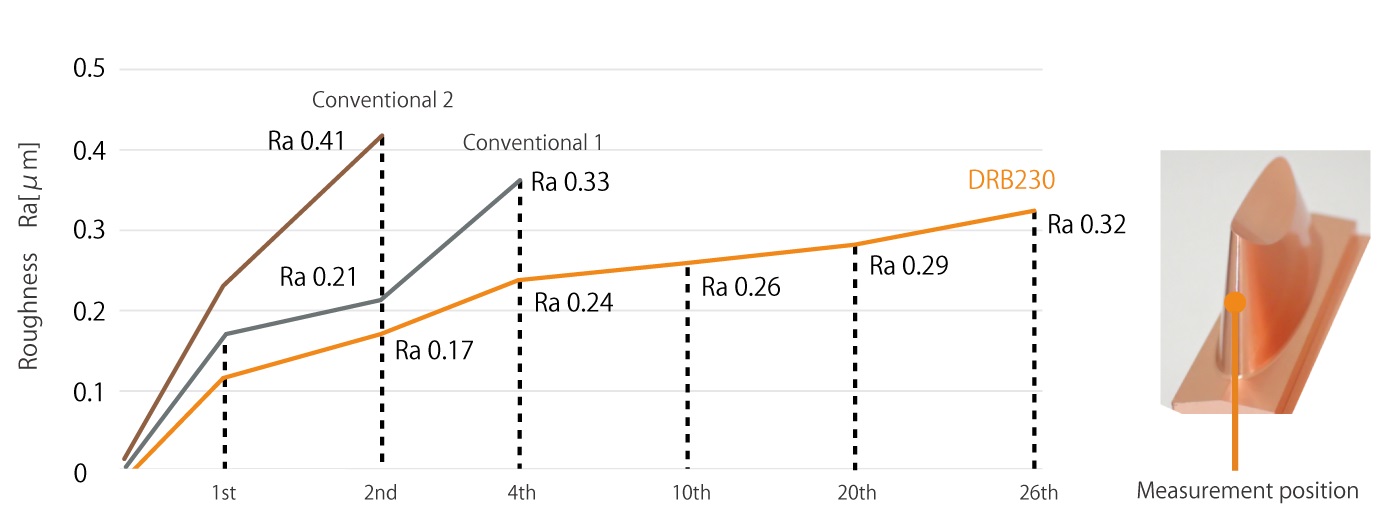

Comparison of roughness