Technology

DHR237 Tough-Pitch Copper Comparison of cutting surface

Material: Tough-Pitch Copper

Work size: 8x15 mm

Cutting depth: 12 mm

Tool

DHR237

●Long neck end mill specialized for machining copper alloy.

●Helix angle 【37.5°】 degrees to achieve both sharpness and finished surface quality that prevents scratches on cutting surface.

●High quality and stable milling performance with long tool life by optimized design and DLC coating.

●Machining copper tungsten electrodes is also effective.

Cutting Conditions

| Process | Finishing | ||

| Tool | DHR230 Φ3×15 |

Other tool brand 1 Φ3×12 |

Other tool brand 2 Φ3×15 |

| Spindle speed (min-1) |

10,000 | ||

| Feed (mm/min) |

600 | ||

| Depth of cut ap×ae(mm) |

4.5×0.03 | ||

| Coolant | Water-insoluble fluid | ||

Comment

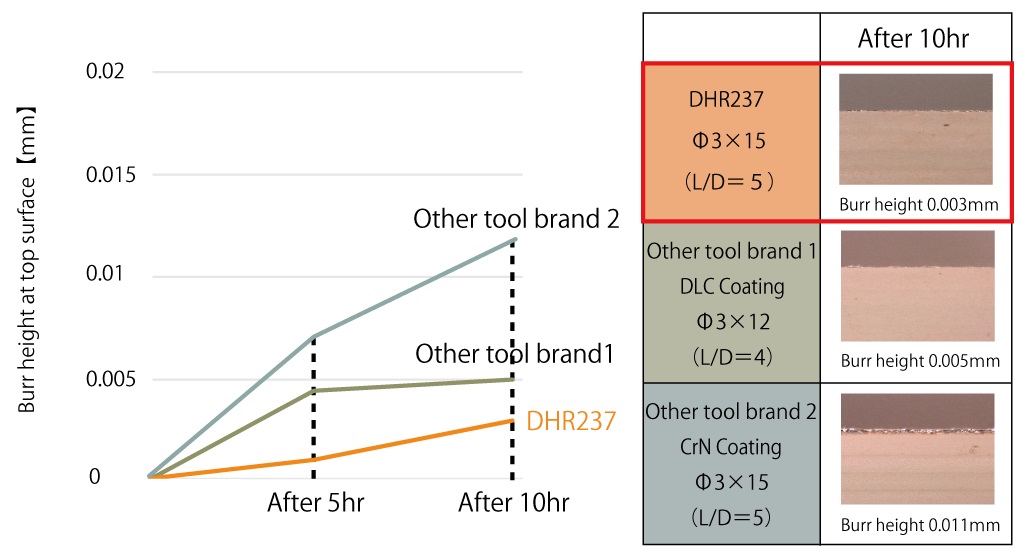

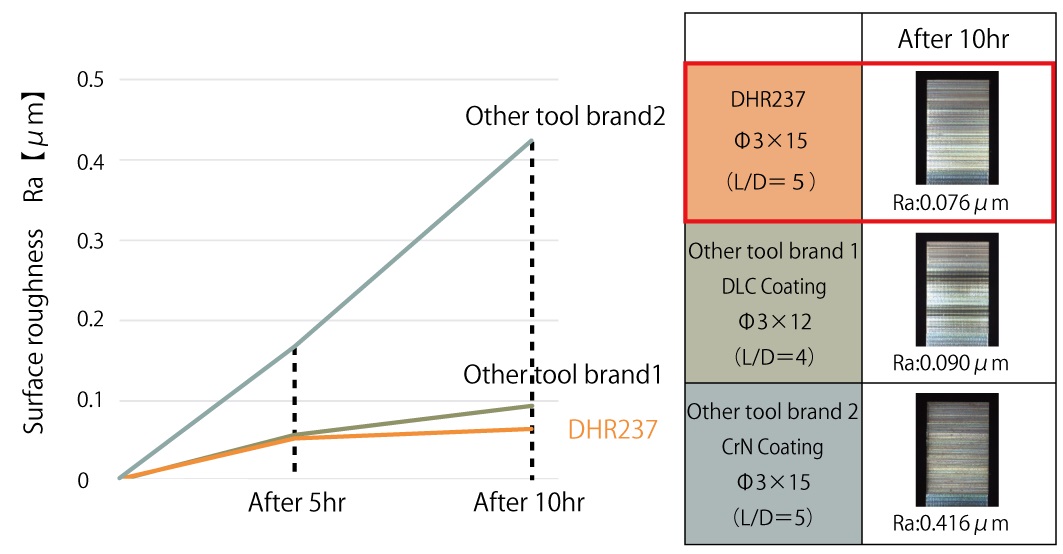

Comparison of cutting surface

After 10 hours machining, DHR237 still can achieve high quality cutting surface.

In the rival products, the processing surface roughness could not be kept constant.

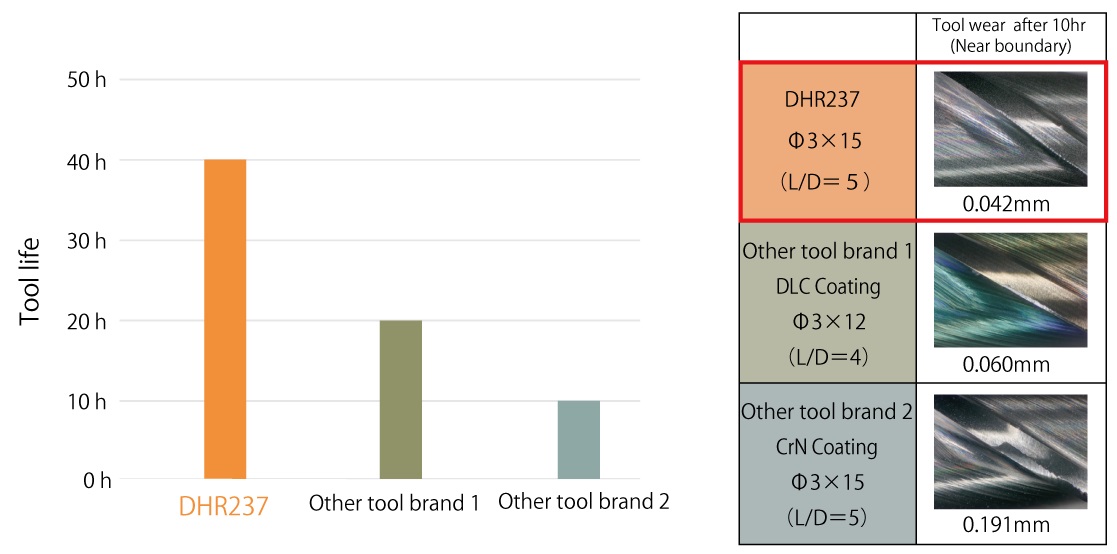

Comparison of tool wear

Because of the 37.5°helix angle, burrs, wave and cutting resistance have been effectively decreased!

DHR237 has 2 times tool life comparing to the rival products.

Upper burr amount

DHR237 suppressed the occurrence of burrs and achieved the sharp edges.