Technology

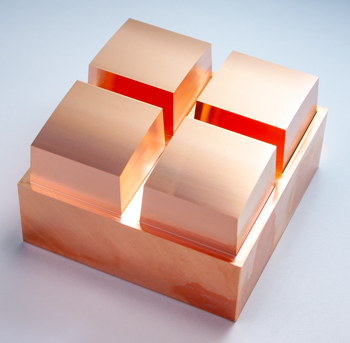

DHR237R Tough-Pitch Copper

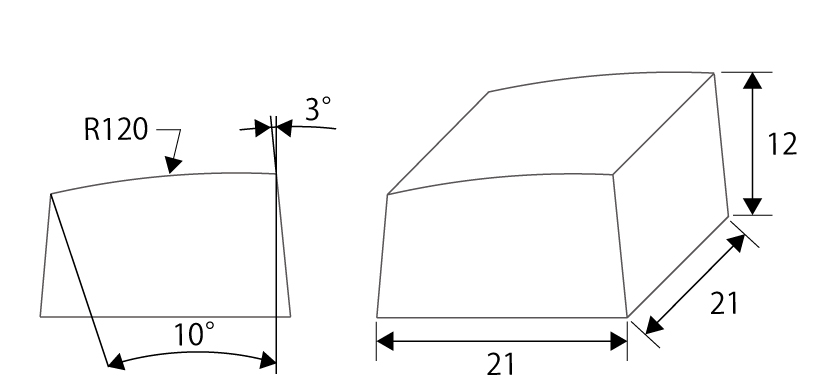

3° curved surface sample Comparison of cutting surface

Material: Tough-Pitch Copper

Work size: 50 × 50 (mm)

Cutting Depth: 12mm

Total cutting time: 11hr 16min

One piece includes 4 shapes, total two pieces

Unit: mm

Tool

DHR237R

●Long neck corner radius end mill specialized for machining copper electrode.

●37.5º helix angle provides both sharpness shearing ability and finishing surface quality, combining the most suitable cutting edge design realizes the higher quality of finishing surface.

●High quality and stable milling performance with long tool life by optimized design and DLC coating.

●Machining copper tungsten electrodes is also effective.

Cutting Condition

| Process | Roughing |

Semi - Finishing (Curved Surface R120) |

Finishing | ||

| Slotting | Contour line | Scanning line | Scanning line | Contour line | |

| Tool | DHR237R Φ3×R0.2×12 Machined by one end mill from roughing through finishing. |

||||

|

Spindle speed (min-1) |

14,000 | ||||

|

Feed (mm/min) |

1,500 | 3,000 | 1,000 | ||

|

Depth of cut (mm) |

ap0.06 | ap0.12 ae1.5 |

ae0.05 | ae0.03 | ap0.03 |

|

Stock (mm) |

0.03 | - | |||

| Coolant | Water-insoluble fluid | ||||

|

Cutting time (1 piece) |

1hr 6min | 4hr 32min | |||

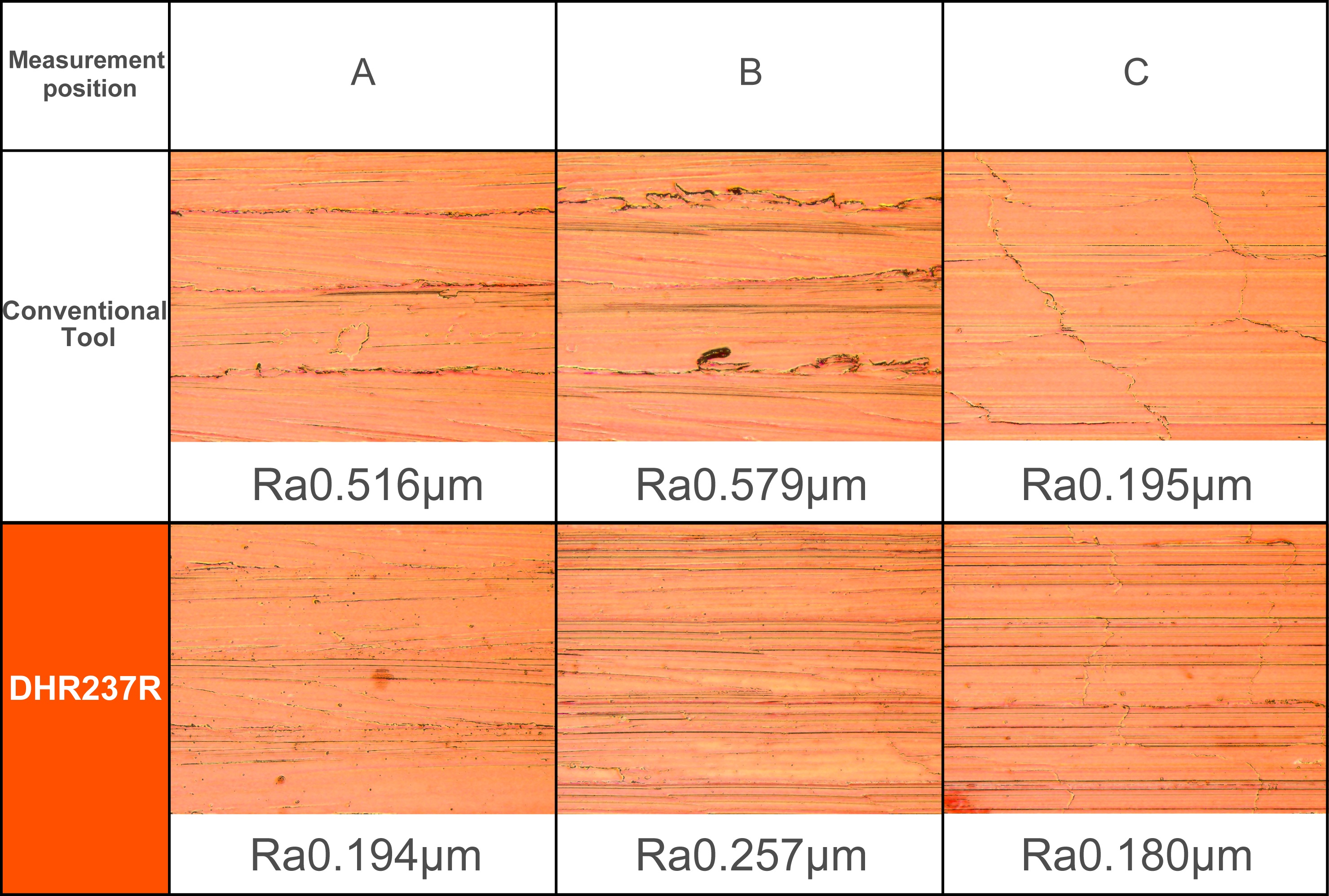

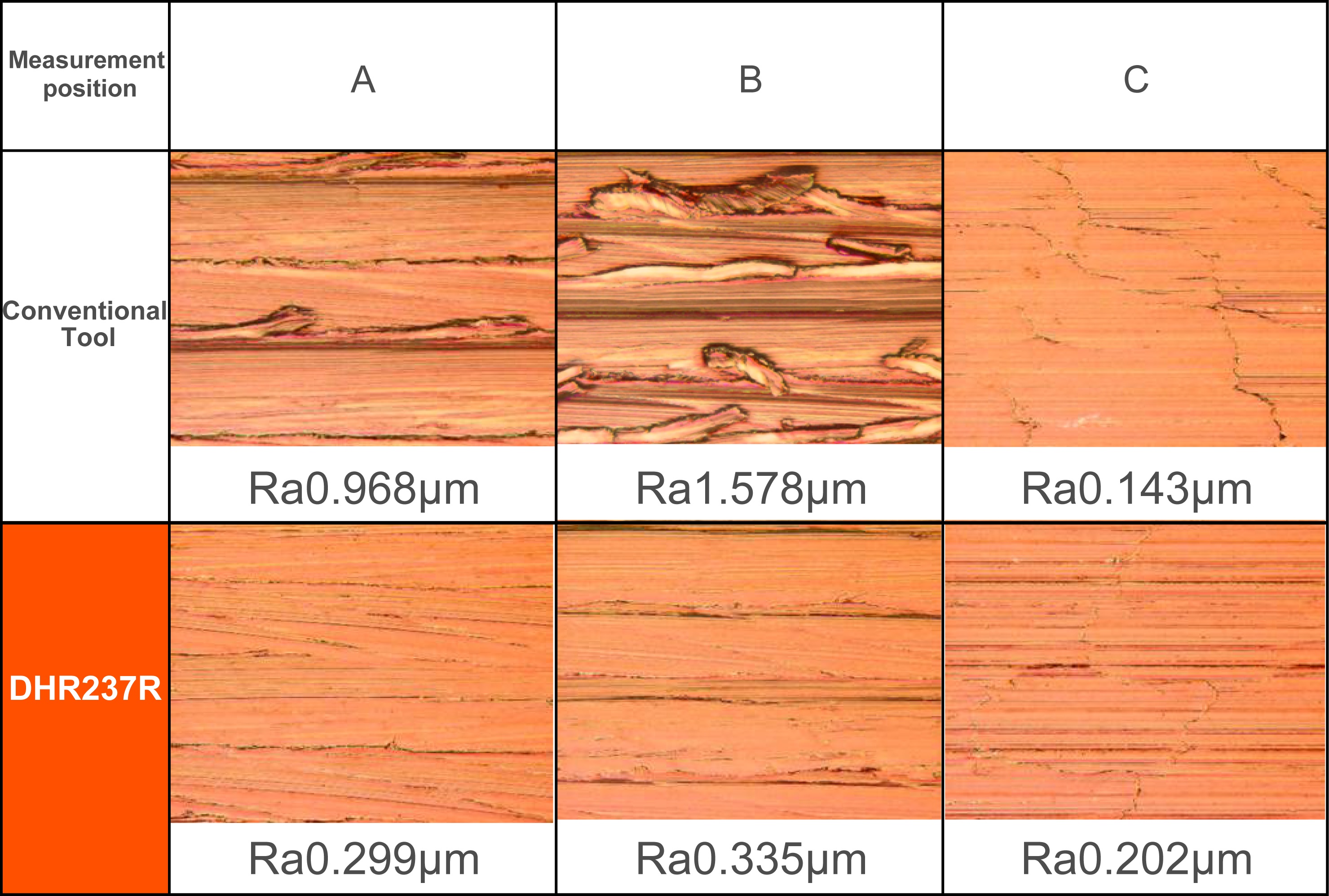

Result

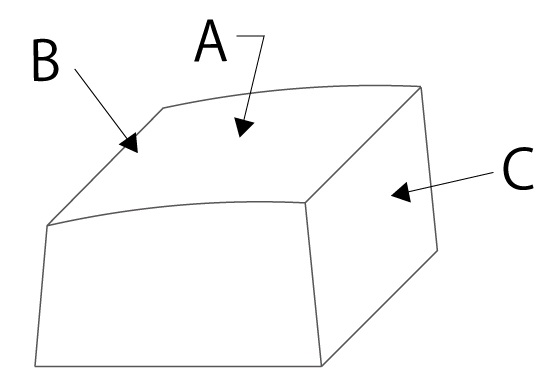

Surface roughness

Measurement position.

1st shape

8th shape

DHR237R can realize no plucking stable surface.

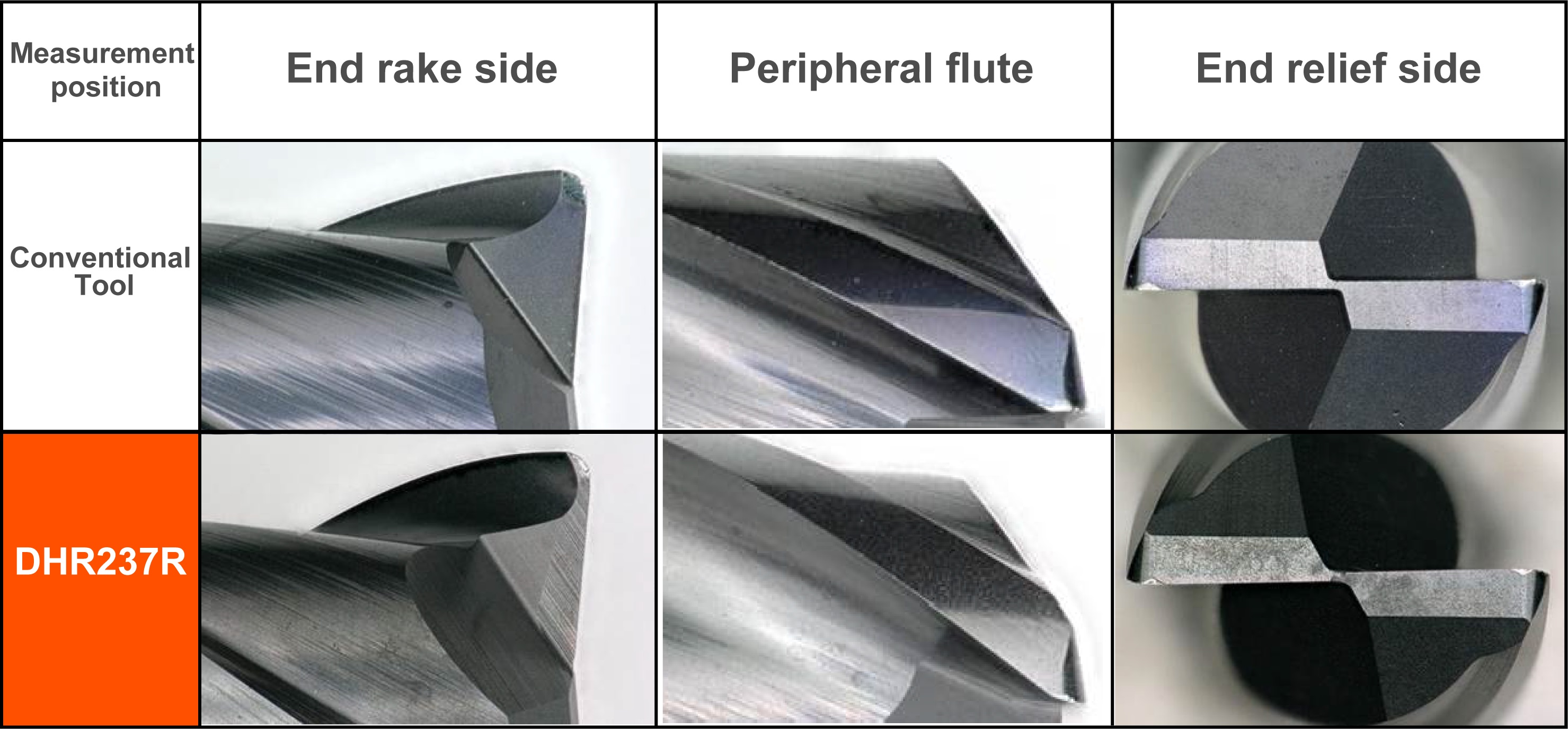

Tool wear

Observant point

DHR237R inhibits wearing progress to achieve continuing stable cutting surface.