Technology

DHR237R Copper Tungsten

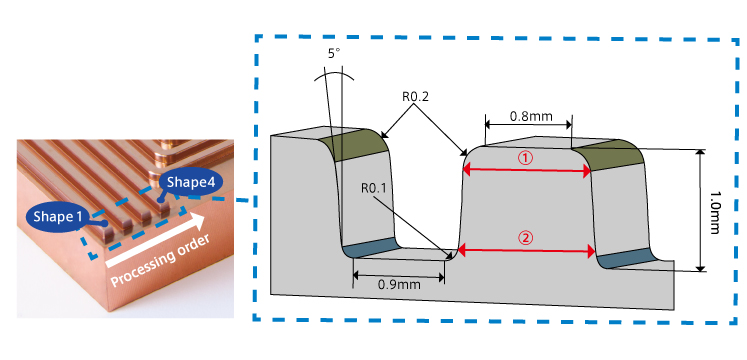

Press Mould Electrode Model

Work size: 30×35mm

(Cutting depth 1 mm)

Material: Copper Tungsten

Cutting time: 2hr 5min

Tool

DHR237R

*Used total 2 tools for machining, one was for roughing and the other was for semi-finishing and finishing.

●Long neck corner radius end mill specialized for machining copper electrode.

●37.5º helix angle provides both sharpness shearing ability and finishing surface quality, combining the most suitable cutting edge design realizes the higher quality of finishing surface.

●High quality and stable milling performance with long tool life by optimized design and DLC coating.

●Machining copper tungsten electrodes is also effective.

Cutting Condition

Roughing ・ Semi-finishing

| Cutting process | Roughing | Semi-finishing | ||

| Contour line | Slotting | Plane | Side | |

| Tool | DHR237R Φ1×R0.1×3 | |||

|

Spindle speed (min-1) |

23,000 | |||

|

Feed (mm/min) |

2,200 | 1,000 | 2,200 | |

|

Depth of cut (mm) |

ap0.054 ae0.55 |

ap0.027 | ae0.05 | ap0.03 |

|

Stock (mm) |

0.05 | 0.03 | ||

| Coolant | Water soluble fluid | |||

| Cutting time | 23min | 30min | ||

Finishing

| Cutting process | Finishing | |||

| Plane | Side | |||

| Tool | DHR237R Φ1×R0.1×3 | |||

|

Spindle speed (min-1) |

23,000 | |||

|

Feed (mm/min) |

1,100 | |||

|

Depth of cut (mm) |

ae0.05 | ap0.02 | ||

| Coolant | Water soluble fluid | |||

| Cutting time | 1hr 12min | |||

Result

Cutting shape details

Cutting Accuracy

| Measurement position | ① 【-0.2mm from the top】 |

② 【-0.8mm from the top】 |

| Target | 1.202mm | 1.307mm |

| Shape 1 | 1.203mm Error :0.001mm |

1.311mm Error :0.004mm |

| Shape 4 | 1.207mm Error :0.005mm |

1.314mm Error :0.007mm |

Surface roughness

(μm)

| Shape1 | Shape4 | |||

| Side | Ra:0.159 Rz:1.403 |

Ra:0.139 Rz:1.018 |

||

| Bottom | Ra:0.055 Rz:0.516 |

|||

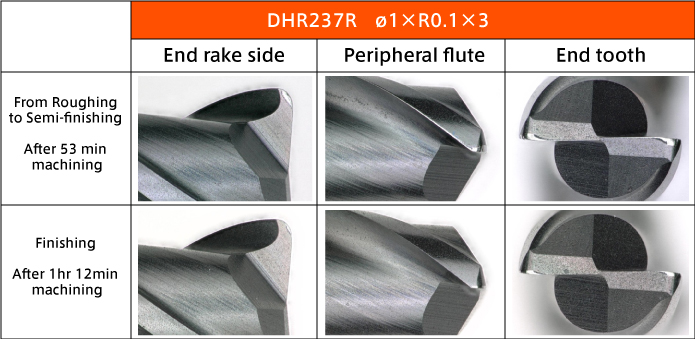

Tool wear

Even through the long time copper tungsten machining, DHR237R can keep stable accuracy and surface roughness.