Technology

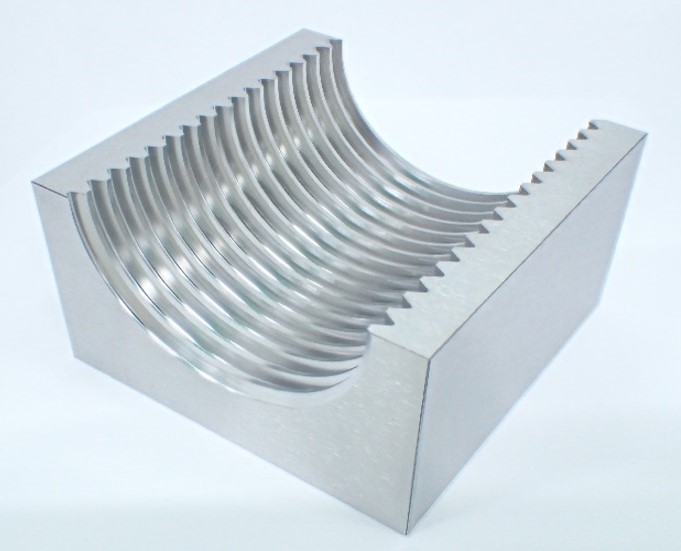

MSBSH330-5X Screw mold

Optimized cut point featured as 5-axis machining to improve surface quality and high rigidity MSBSH330-5X realizes high accuracy and high efficiency machining performance.

Material : DC53(60HRC)

Work size : 50×50mm

Cutting depth : 20mm

Coolant : Oil mist

Total machining time : 14hr54min

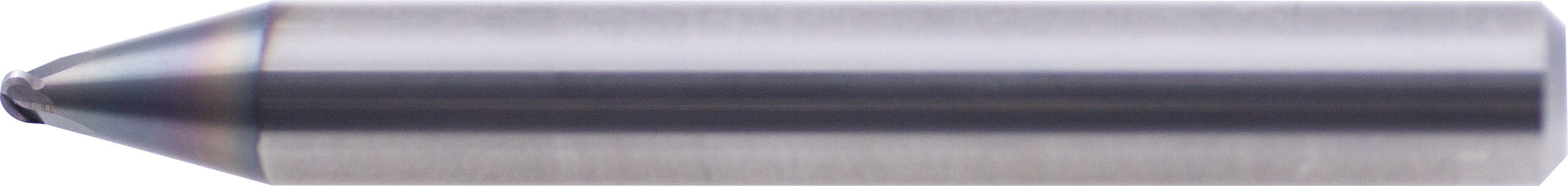

Tool

MSBSH330-5X

●3-flute high rigidity ball design conforms features of 5-axis machine to reduce total manufacturing cost with high precision and high efficiency machining.

●Even hardened steel of 45 to 70HRC can be machining with long tool life and high efficiency.

●By adopting positive cutting edge for carbide material emphasized breakage resistance that suppresses chattering by 3-flute and unequal flute.

●R accuracy is ±0.005mm (R accuracy is based on a half value of actual diameter).

●Shank diameter tolerance, high accuracy type, is - 0.001~- 0.003.

Cutting condition

| Process | Roughing① | Roughing② | Stock removal | Semi-finishing | Finishing | ||

| Tool | MSBSH330-5X R1 | MSBSH330-5X R0.5 | MSBSH330-5X R0.3 | MSBSH330-5X R0.3 | MSBSH330-5X R0.3 | ||

| Spindle speed (min-1) |

25,000 | 25,000 | 30,000 | 30,000 | 40,000 | 40,000 | 40,000 |

| Feed (mm/min) |

3,000 | 1,500 | 1,500 | 1,500 | 1,500 | 1,500 | 1,500 |

| Depth of cut ap×ae(mm) |

0.2 × 0.5 | 0.07 × 0.09 | 0.08 × 0.2 | 0.06 × 0.06 | 0.015 × 0.035 | 0.03 × 0.03 | 0.02 × 0.02 |

| Stock (mm) |

0.1 | 0.03 | 0.025 | 0.015 | 0.015 | 0.005 | 0 |

| Tilt (°) |

20° ~ 40° | 0° ~ 30° | 10° | 3° | 3° | ||

| Time | 2hr 6min | 27min | 1hr 21min | 53min | 2hr 10min | 3hr 11min | 4hr 46min |

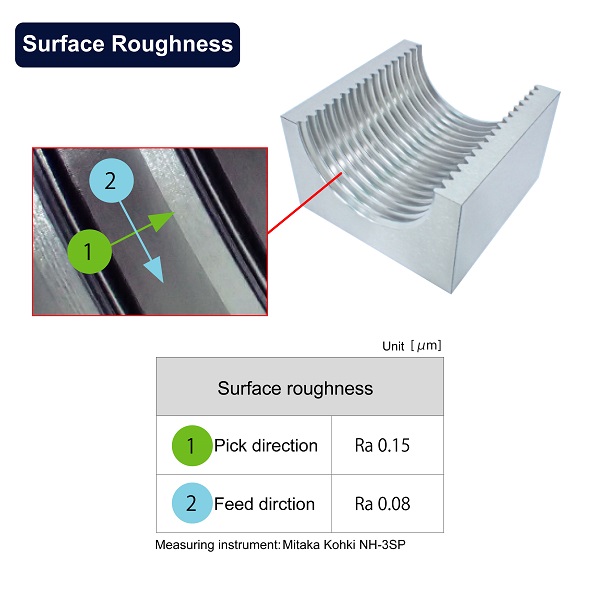

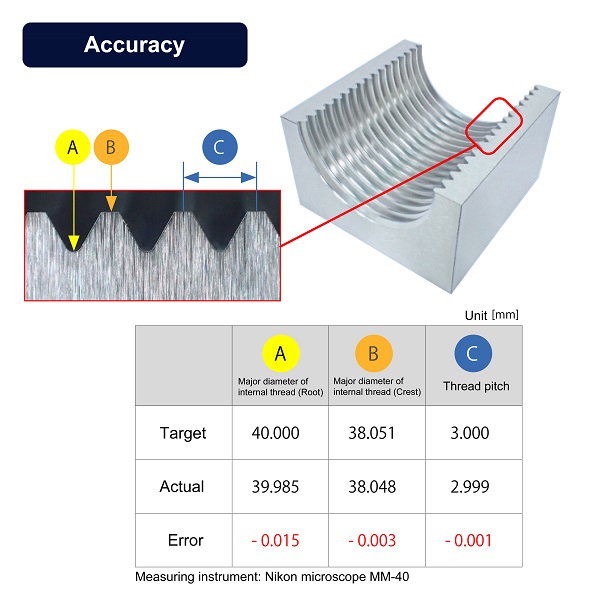

Result