Technology

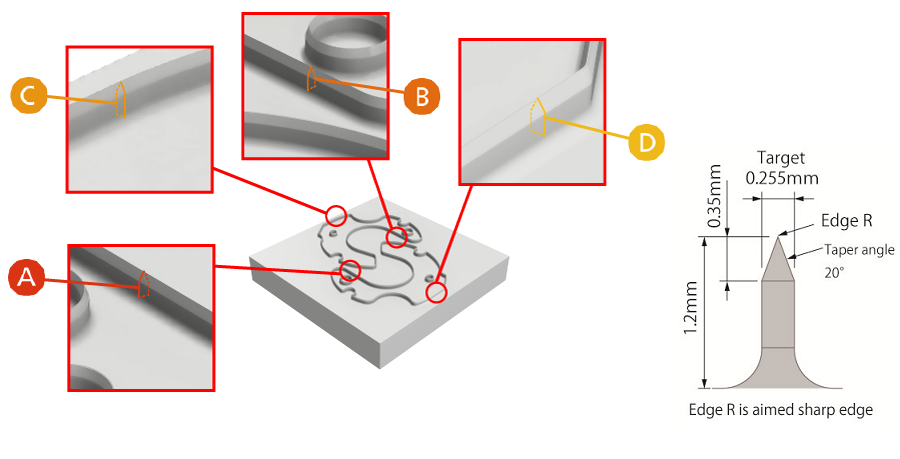

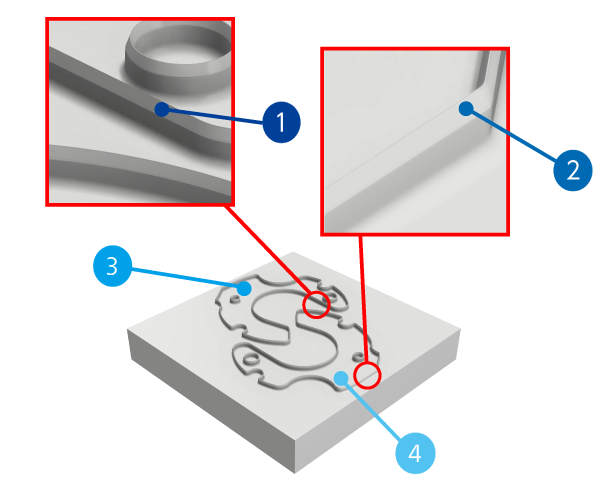

MRBSH330 Die cutter for Insulation sheet

Realize high efficient machining on micro shape machined by small diameter end mill

Work material : HAP40(64HRC)

Work size : 50×50mm

Depth of cut : 20mm

Coolant : Oil Mist

Total machining time : 6hr52min

Tool

MRBSH330

●High-efficiency 3-flute ball end mill optimizes a shape of central edge and enables high depth of cutting.

●Even hardened steel of 45 to 70HRC can be machining with long tool life and high efficiency.

●R accuracy is ±0.005mm (R accuracy is based on a half value of actual diameter).

●Shank diameter tolerance , high accuracy type, is - 0.001 ~ - 0.003.

Cutting condition

|

|

| Finishing area ① | Finishing area ② |

| Process | Roughing① | Finishing① | Roughing② | Roughing③ | Semi-finishing | Finishing② |

| Tool | MRBSH330 R1×3 |

MRBSH330 R0.5×2 |

MRBSH330 R0.3×1 |

MRBSH330 R0.3×1 |

||

| Spindle speed (min-1) |

20,000 | 25,000 | ||||

| Feed (mm/min) |

3,000 | 1,500 | 2,100 | 1,080 | 800 | |

| Depth of cut ap×ae(mm) |

0.23 × 0.3 | ae 0.05 | 0.02 × 0.1 | 0.015 × 0.05 | Z pitch 0.02 | Side:Z pitch 0.003~0.01 Bottom:ae 0.05 |

| Stock (mm) |

0.05 | 0 | 0.03 | 0.015 | 0.005 | 0 |

| Time | 37min | 33min | 1hr26min | 42min | 39min | 2hr55min |

Result

【Accuracy】

Unit[mm]

|

|

|

|

||

| Width | Target | 0.255 | |||

| Actual | 0.260 | 0.258 | 0.259 | 0.260 | |

| Error | +0.005 | +0.003 | +0.004 | +0.005 | |

| Edge R | 0.0018 | 0.0027 | 0.0025 | 0.0025 | |

【Surface roughness】

Unit [μm]

|

|

|

|

|

| Ra | 0.070 | 0.070 | 0.303 | 0.328 |

| Ra | 0.387 | 0.355 | 1.719 | 1.699 |