Technology

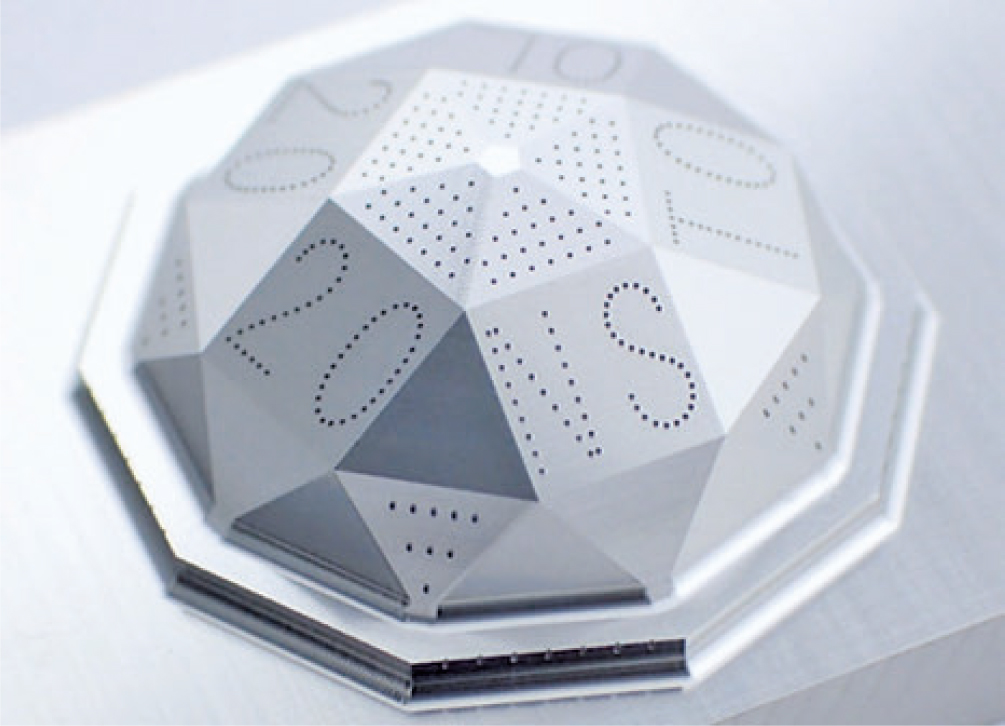

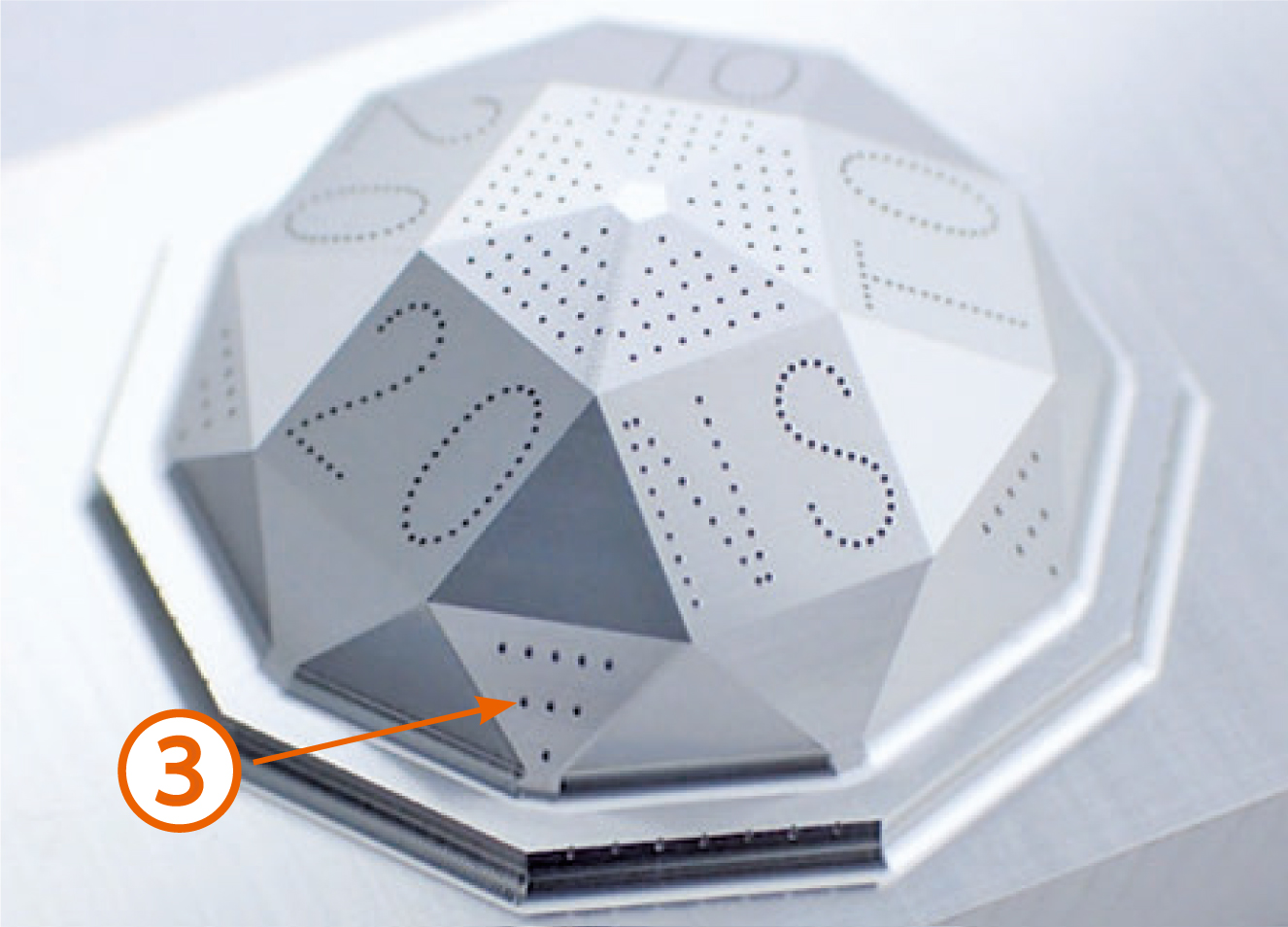

MFD Cutting example of drilling on the inclined surface

Work size:20×30(mm)

Material : SUS304

Coolant : Water soluble fluid

Machining time : 1hr 3min (Drilling only)

Tool

MFD

●Tool design developed and optimized for different sizes.!

●Stable drilling is realized in various scenes such as inclined surface and curved surface!

●High efficient counter boring is available, also possible to reduce the burr.

Milling Conditions

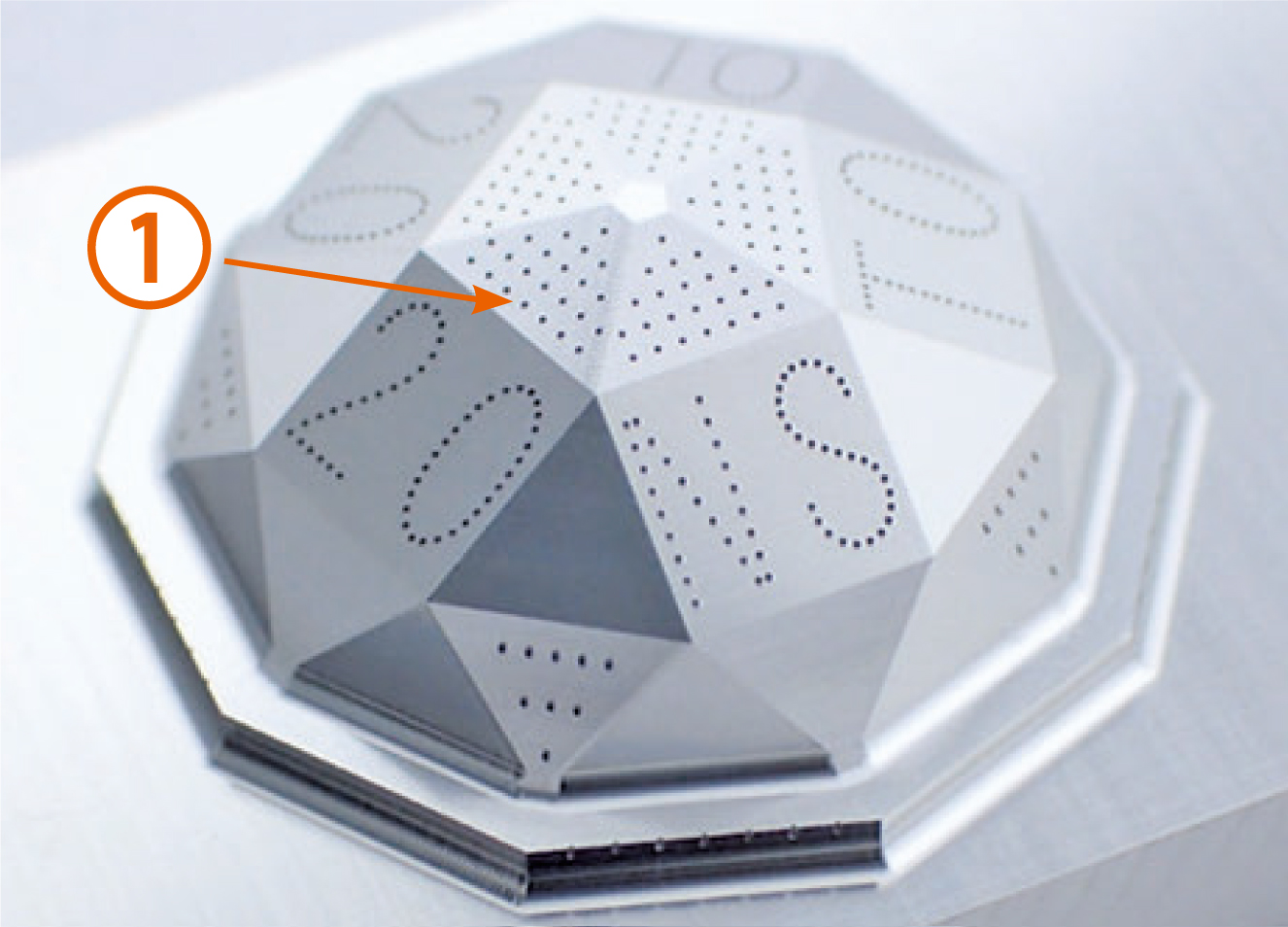

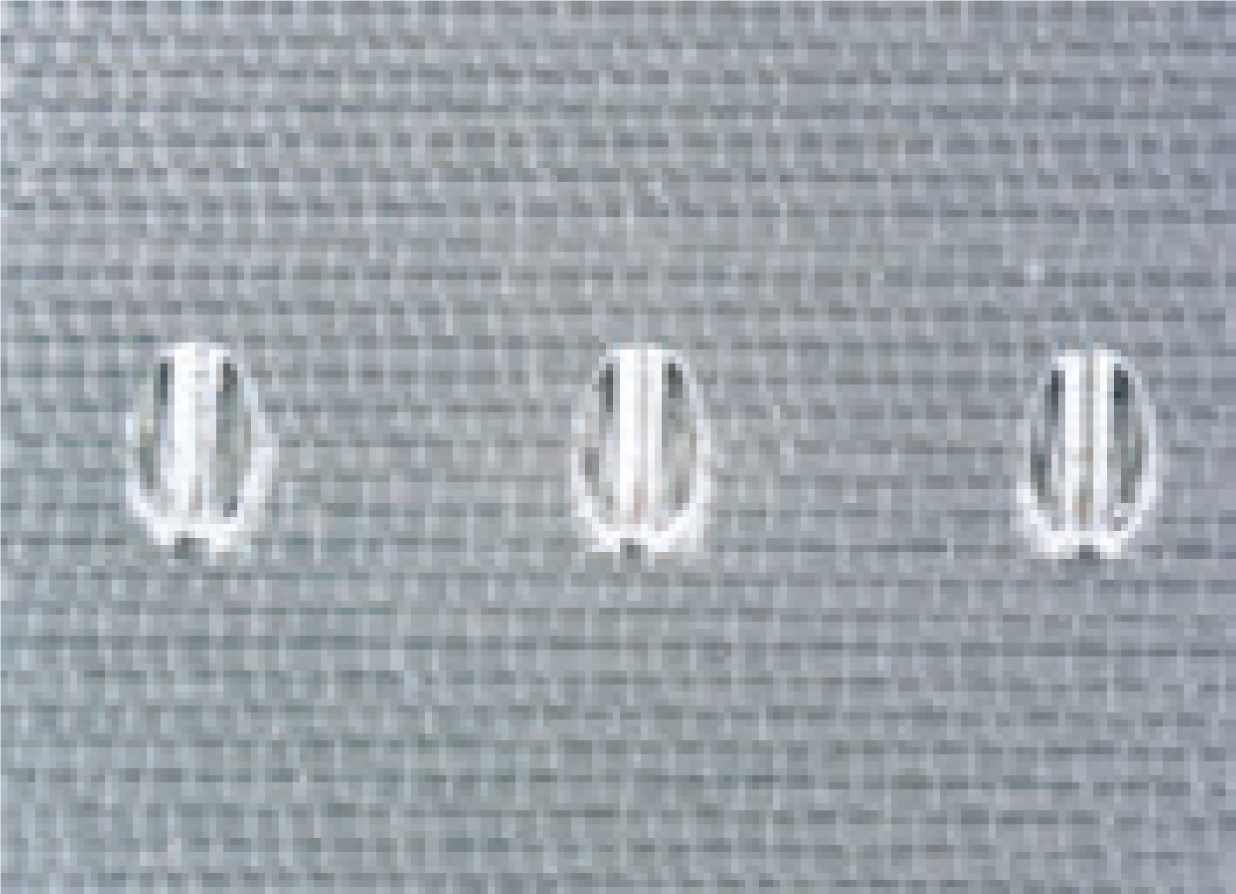

①Slope【 Inclined angle 15° (Blind hole)】

| Spindle speed (min-1) |

25,000 |

| Feed (mm/min) |

3 |

| Cutting depth | 0.2mm (Non-Step) |

| Machining time (mm) |

8sec/hole |

Hole diameter:0.101mm

115holes

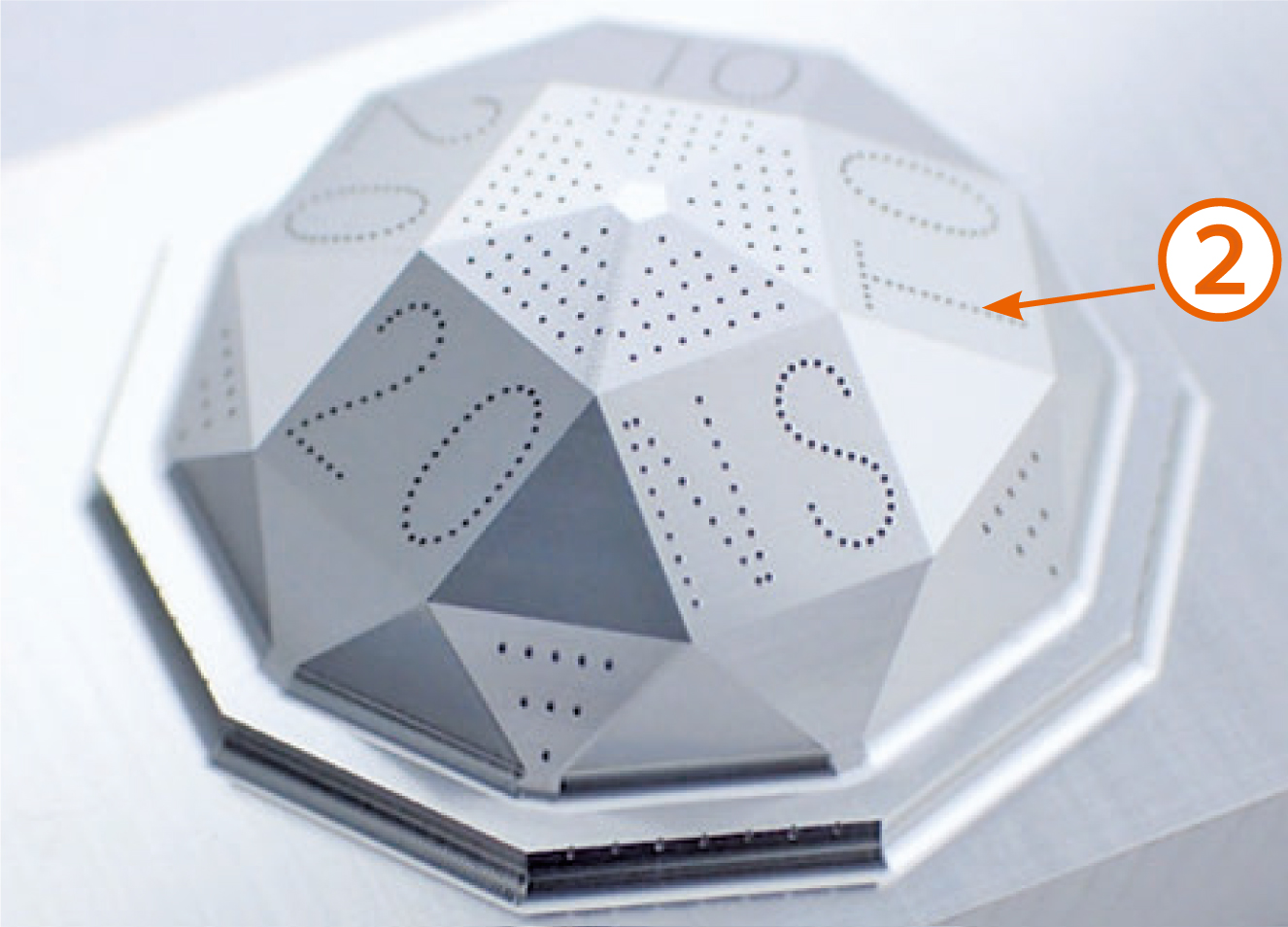

②Slope【 Inclined angle 30° (Blind hole)】

| Spindle speed (min-1) |

25,000 |

| Feed (mm/min) |

3 |

| Cutting depth | 0.2mm (Non-Step) |

| Machining time (mm) |

8sec/hole |

Hole diameter:0.104mm

256holes

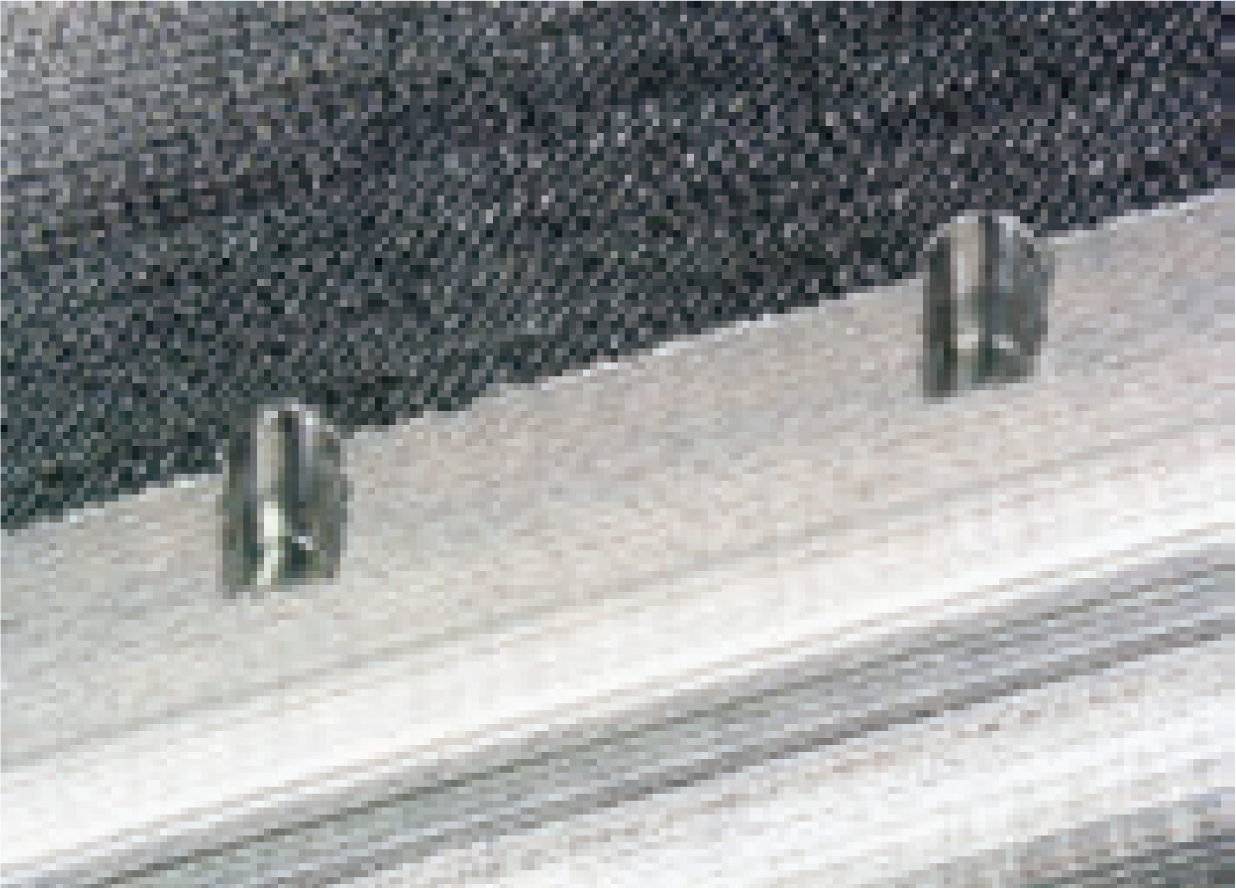

③Slope【 Inclined angle 70° (Blind hole)】

| Spindle speed (min-1) |

25,000 |

| Feed (mm/min) |

2 |

| Cutting depth | 0.2mm (Non-Step) |

| Machining time (mm) |

10sec/hole |

Hole diameter:0.100mm

45holes

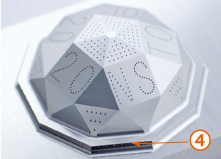

④Semicircular hole

| Spindle speed (min-1) |

25,000 |

| Feed (mm/min) |

2 |

| Cutting depth | 0.2mm (Non-Step) |

| Machining time (mm) |

10sec/hole |

Hole diameter:0.100mm

35holes